Michael’s Triumph T100

This is perhaps a cautionary tale for anyone who hopes that bolting on an aftermarket headlight to a Hinckley twin is a simple job.

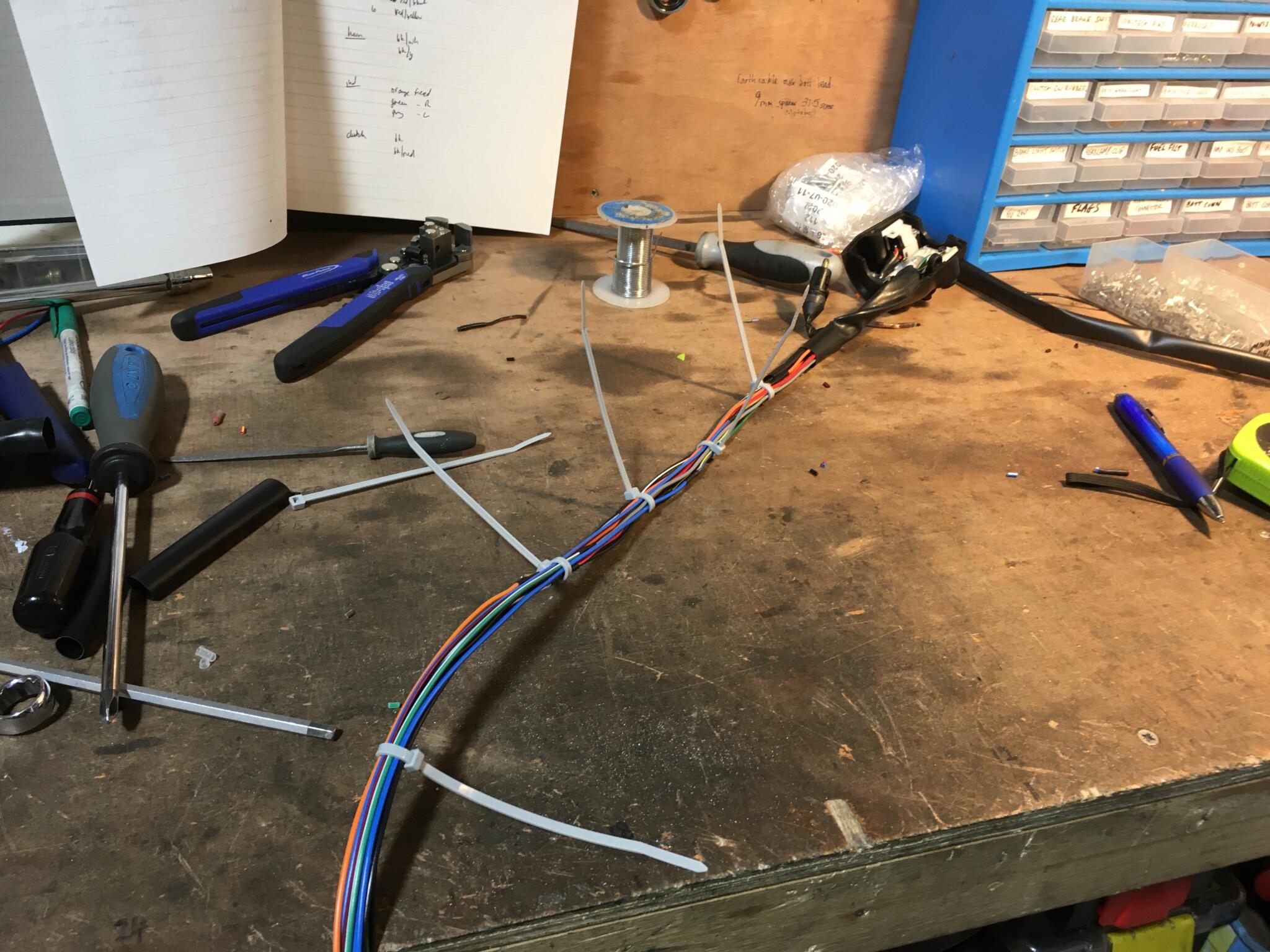

Michael had been slowly modifying his T100, and reached the point where he wanted to fit a smaller headlight. Unfortunately the existing headlight was full of electrics. He made a good job of chopping and relocating the gubbins so that everything still worked – but he wasn’t happy with how it looked. So he brought it along to the workshop.

In my experience, relocating bits of a standard loom is really difficult. At one end at least, you are stuck with the wiring joins and routings that the manufacturer designed. At the other, you might not be able to unplug, say, the speedo, from its wires. You also have to remember what all the wires actually do, all the time that they are dangling in space after you’ve got busy with the side cutters. On top of that there’s rarely enough space to stagger the cuts and joins, so you risk making a big fat bulge somewhere.

It can all be fixed if you have endless time and money, but otherwise you have to pick a point between ‘almost perfect’ and ‘that’ll do’. I managed to get away with only having to wrap two of the wire bundles, so that felt like a win.