With a highly modified bike you have to spend ages designing and building sub-systems. This is the fuse array

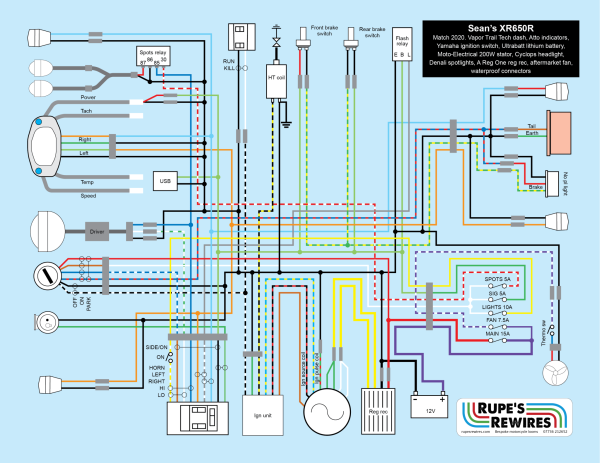

Sean’s XR650 overland bike

This bike is so complicated and ambitious it’s really exciting. Owner Sean is planning a big trip to the Americas and beyond, and the bike is Honda’s water cooled XR650 enduro racer. It’s got huge suspension, no battery and moped-basic lighting. His plan is more suited to multi-country travel: high power lighting, USB charging, an ignition switch, a Vapor dash and – to power it all – a new alternator stator plus reg rec to charge a battery.

Fitting all this stuff to a racebike with absolutely no space asks for some very creative thinking. The lights were already mounted but the Denali spots were shaded by the front mudguard. Scott the fabricator made some amazing brackets to put the spots up high where their beams could light the road ahead without obstruction. The right hand bracket also acts as a mount for the fuses. The USB charger snuck in next to the dash, and the Yamaha ignition switch sits on its own chunky bracket. The regulator rectifier squeezed in under the seat, but the battery was a real headache.

The only place it could go (without getting overheated or hammered by gravel) was under the rear luggage rack. That meant chopping the rack up, extending it upwards, making a box, making a water resistant lid, welding the box to the rack and fitting a closing strap. Not the sort of thing you can accomplish in half a day.

While Scott got busy with making the battery box and modifying the pannier racks so that they actually fitted the bike I worked out how to fit a roadbike loom into a racebike space. The tricky part is at the front in the headlight area. You need to create separate leads for the dash, indicators, USB charger, spotlight relay and connector plugs, main light driver, ignition switch, left switchgear plug, fuse box plug, horn and front brake switch. And it all needed to be as waterproof as possible.

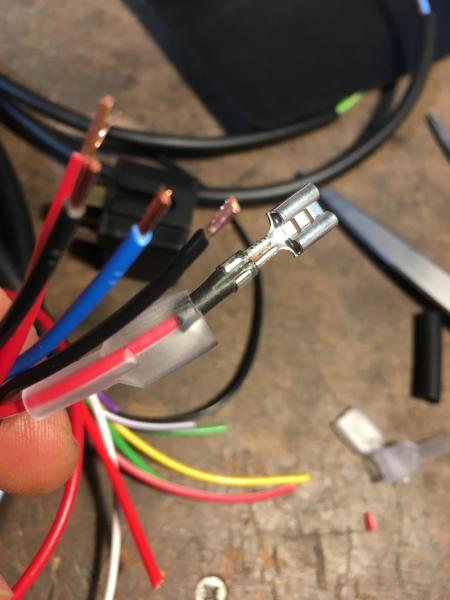

I used Delphi sealed plugs for the big connectors, and custom-sealed Japanese bullets for everything else. Basically you crimp the bullet over an extra PVC sleeve and use lots of silicone grease on the insulators. It’s a pretty watertight solution that takes up minimal space. When you add a lot of separate goodies to a bike in one place it can get quite congested feeding wires to them all, so the modified bullet solution is a good way through.

The aftermarket alternator is giving us a bit of bother (more on that when we know) but otherwise Sean’s transcontinental electrical aspirations have been met. It’s an incredible motorcycle.

A simple way to seal bullet connectors: slide on a section of 2mm PVC sleeve and crimp it. Lubed with silicone grease it’s pretty watertight

Ignition box is in its original position. Flasher unit, tail and charging connectors, and regulator rectifier squeeze next to it

Scott’s battery box with its milled Acetal lid. You might think this is a funny place to put a battery but on a no-battery racer there’s nowhere else!