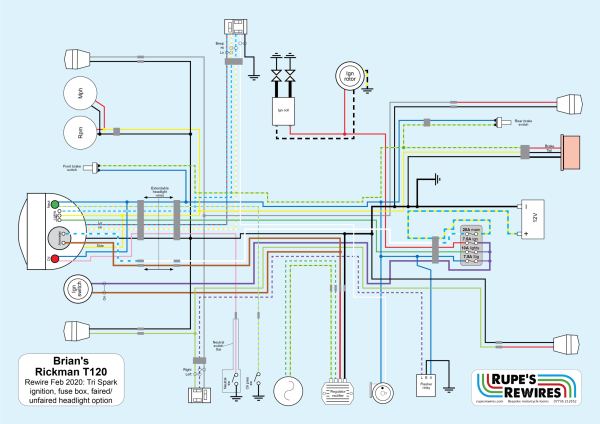

Brian’s Rickman Triumph T120

Brian was lucky enough to acquire one of the last Rickman Metisse frames built by Pat French. Designed for road racing, these frames combined top quality welding and materials with excellent design. Brian used his to build up a true English cafe racer, with a Triumph T120 engine. He had a go at the electrics but wasn’t happy with the result, so booked the bike in for a new loom.

Being built to race, the frame only had a bracket for the ignition coil – nothing for the road electrics that Brian needed. So the first job was to mount these items securely. Fabricator Scott made an elegant pair of brackets which screwed to the coil mounts to carry the ignition switch, flasher unit, oil pressure switch and fuses.

The only place we could find for the horn was between the downtubes, so that needed a third bracket and 1.6mm machining off each engine spacer to suit. Brian had already incorporated a battery box into the oil tank, and that created an obvious home for the regulator rectifier.

These sound like boring details, but on a vibrating British twin they’re the difference between a bike that will keep going and one that breaks down. Getting it all neat and functional takes a long time.

The headlight is another critical point on old Brit machinery, especially (as here) when it has an ammeter, a light switch and a couple of warning lights poking into the headlamp shell. People often leave the ammeter terminals bare, then force the headlight in and wonder why the fuse keeps blowing. (If they’ve fitted a fuse!) I secured the shell components with glue, insulated everything properly, and made sure the headlight plug didn’t foul anything else in there.

The loom itself was fairly straightforward but Brian has a top half fairing for the bike and wants to try it with and without wind protection. So we needed a ‘plug in’ extension on the headlight harness, and very long indicator cables which looped neatly out of the way for the naked version, or extended for the faired one.

It fired up, but didn’t run too happily: the carbs needed a clean. Modern fuel blocks Amal pilot jets amazingly quickly if the bike sits for a bit. Brian is seeing to that and a couple of other details, just in time for a fun summer on a unique machine.