Floydy Racing engine build, Zeeltronic ignition, phenomenal exhausts by Mark Dent at Performance Fabrications

Dave and Ian’s TDR250s

This was actually two TDR250s one after the other, but I forgot to take many pics of the second one which belongs to Ian Davis of the superb ETTO Motorcycles. ETTO stands for each to their own and it’s one of the best custom engineering shops in the UK. One day, you’ll see his one finished, and it will be awesome.

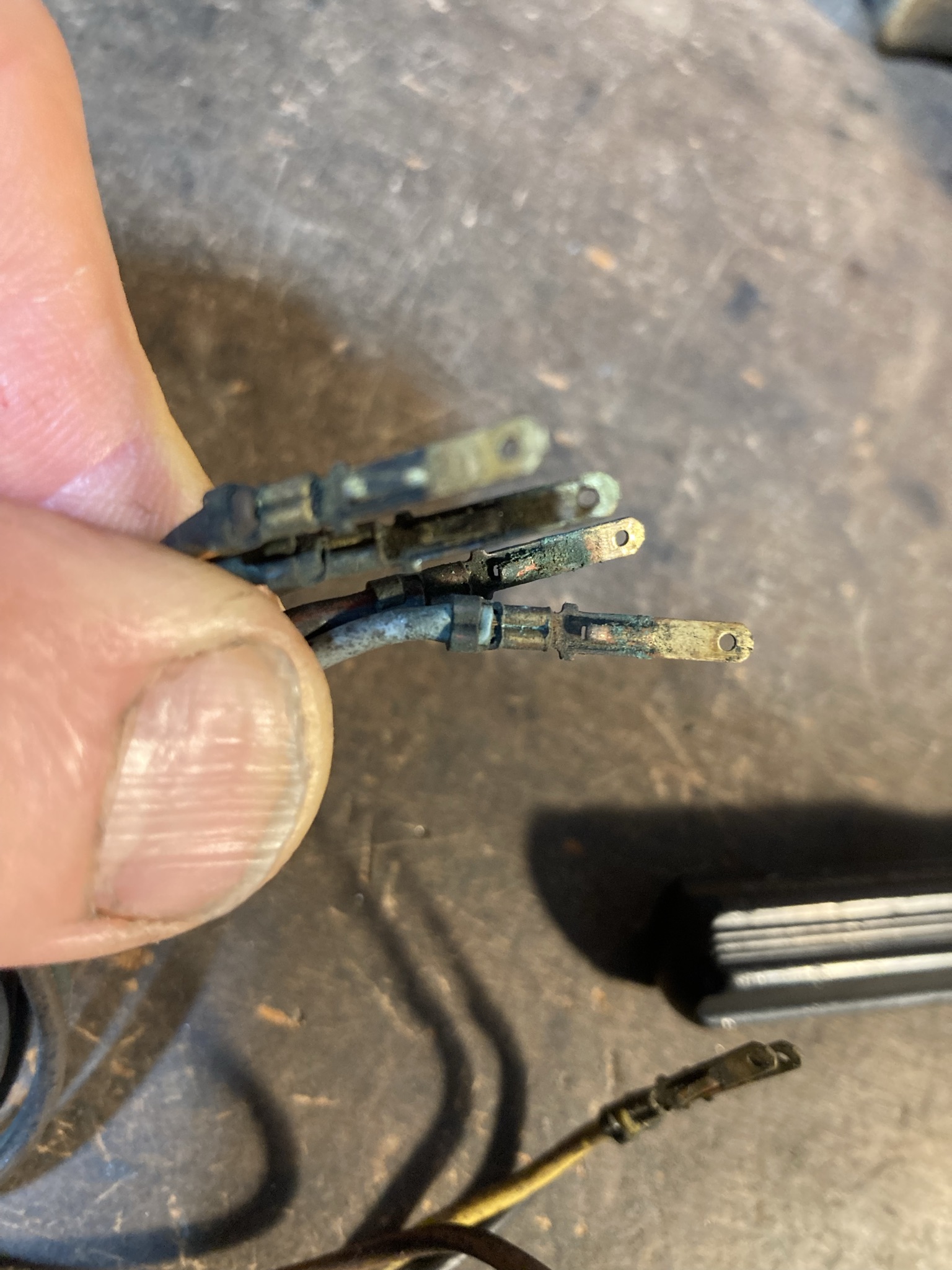

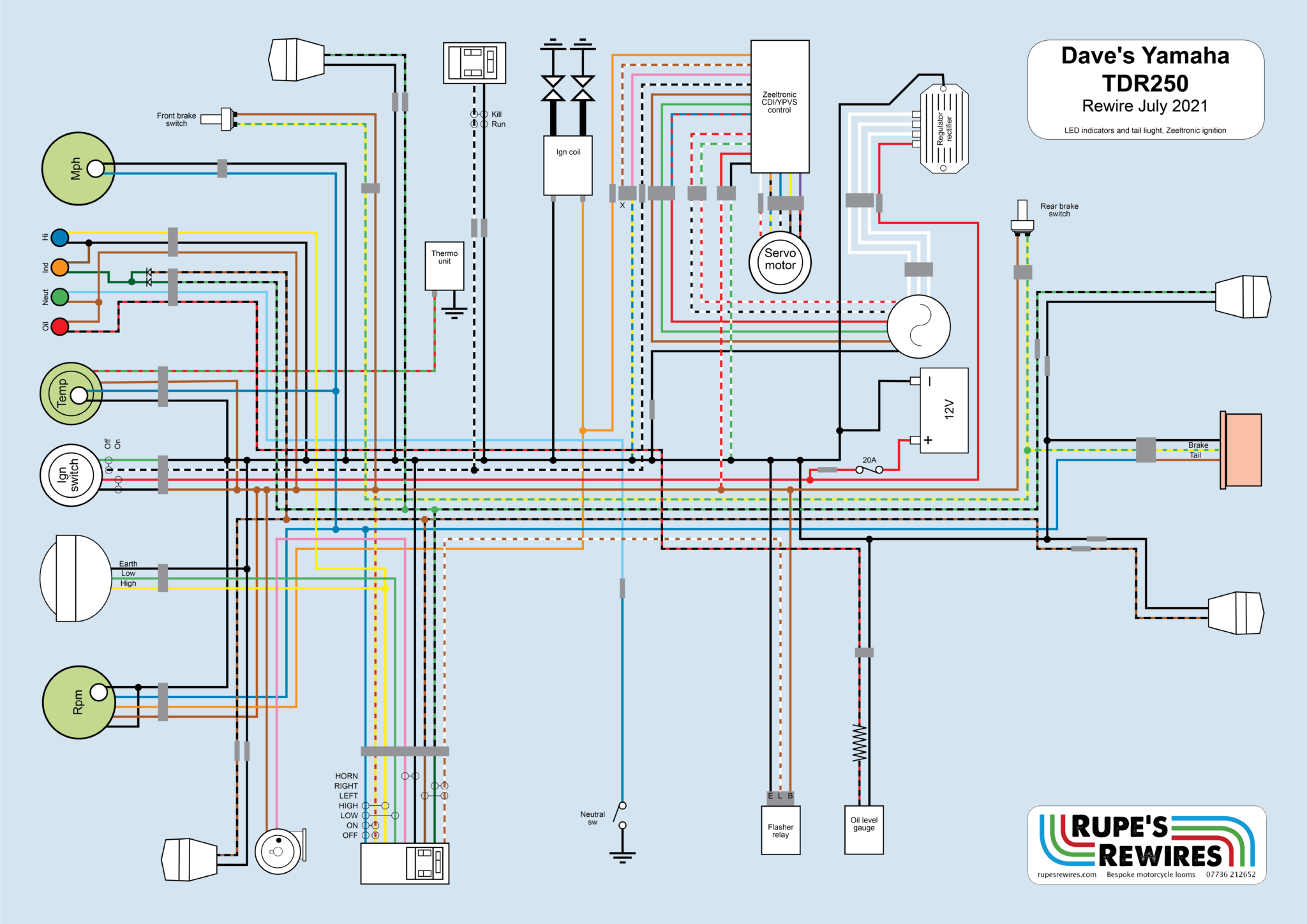

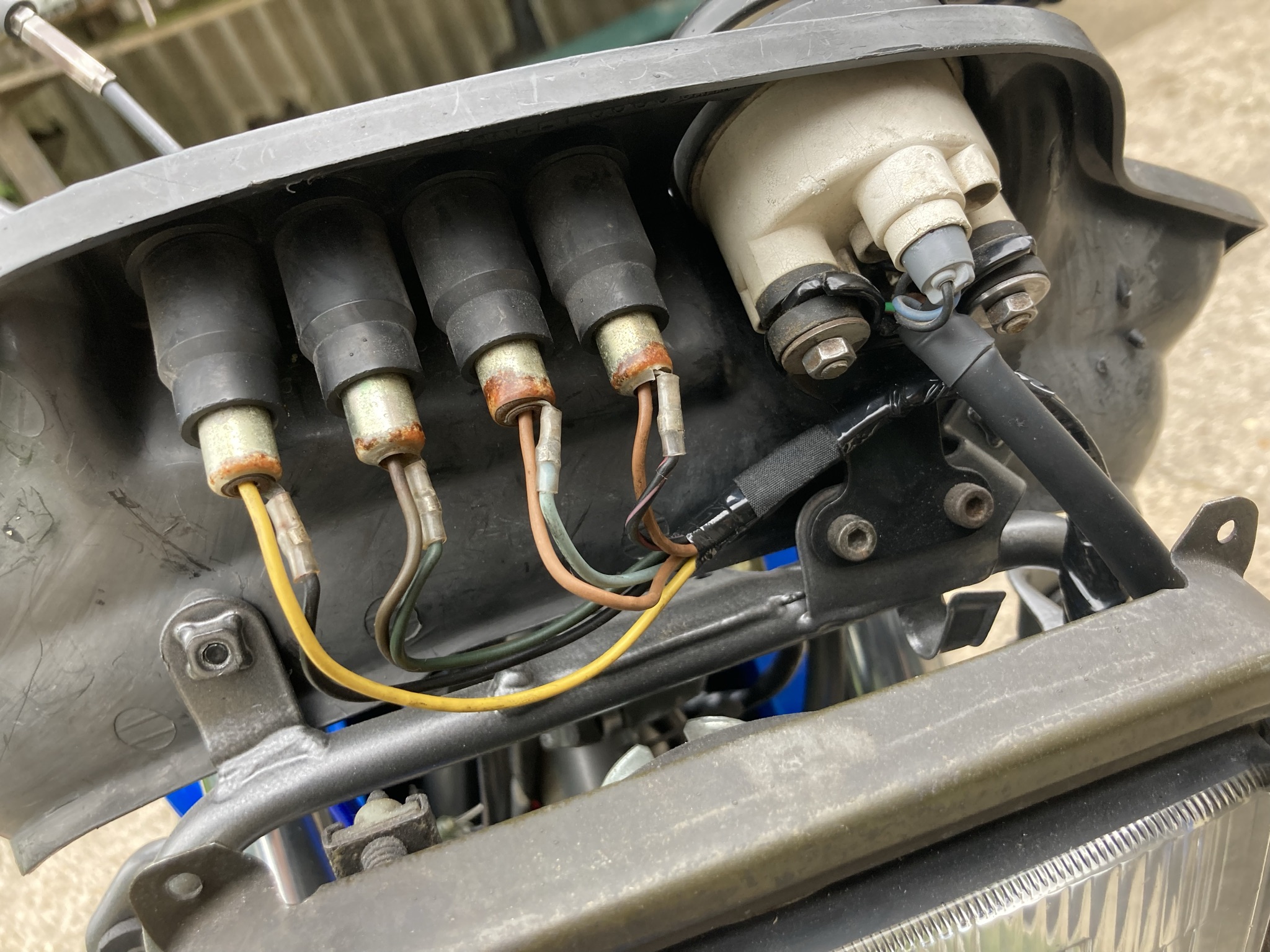

Also pretty neat is the one you see here, belonging to Dave, who works just up the road from Ian. The loom itself isn’t too complicated (though if you want to keep the original ignition system connectors only Kojaycat can provide them. But I digress). The big thing with TDRs is chasing out all the tiny sources of unreliability. Wires get chafed, corrosion creeps in, bulbs seize in their holders, and previous owners behave like apes with spanners.

Anyway, they got new looms. I decided to wrap them because that’s what Yamaha did, and anyway the odd central design, which is like a spider, won’t work with any other method.