Les’s Honda NT700 Hawk special

The Hawk is, by a country mile, the best bike we never got to see in the UK. Les’s bike is, like most Hawks, a US market model.

I haven’t had a 1990s Honda in the shop for a while, and I was amazed how beautifully designed and thought about this thing is. Honda back then had lots of money, and were building bikes of unbelievable quality. The Hawk is a narrow-angle V twin 650 with sporty pretensions. The nearest we got here was the shaft-driven 600 Revere, which was a nothing bike if ever there was one. I know – I rode one to the south of Spain and back.

Les has a thing about Hawks. He has quite a few in various states of completeness (as well as an XS 650 Yamaha which I rewired a while back). This is the first Hawk special he did, with a custom seat, tail light and nose fairing, and an engine bored out to 700cc.

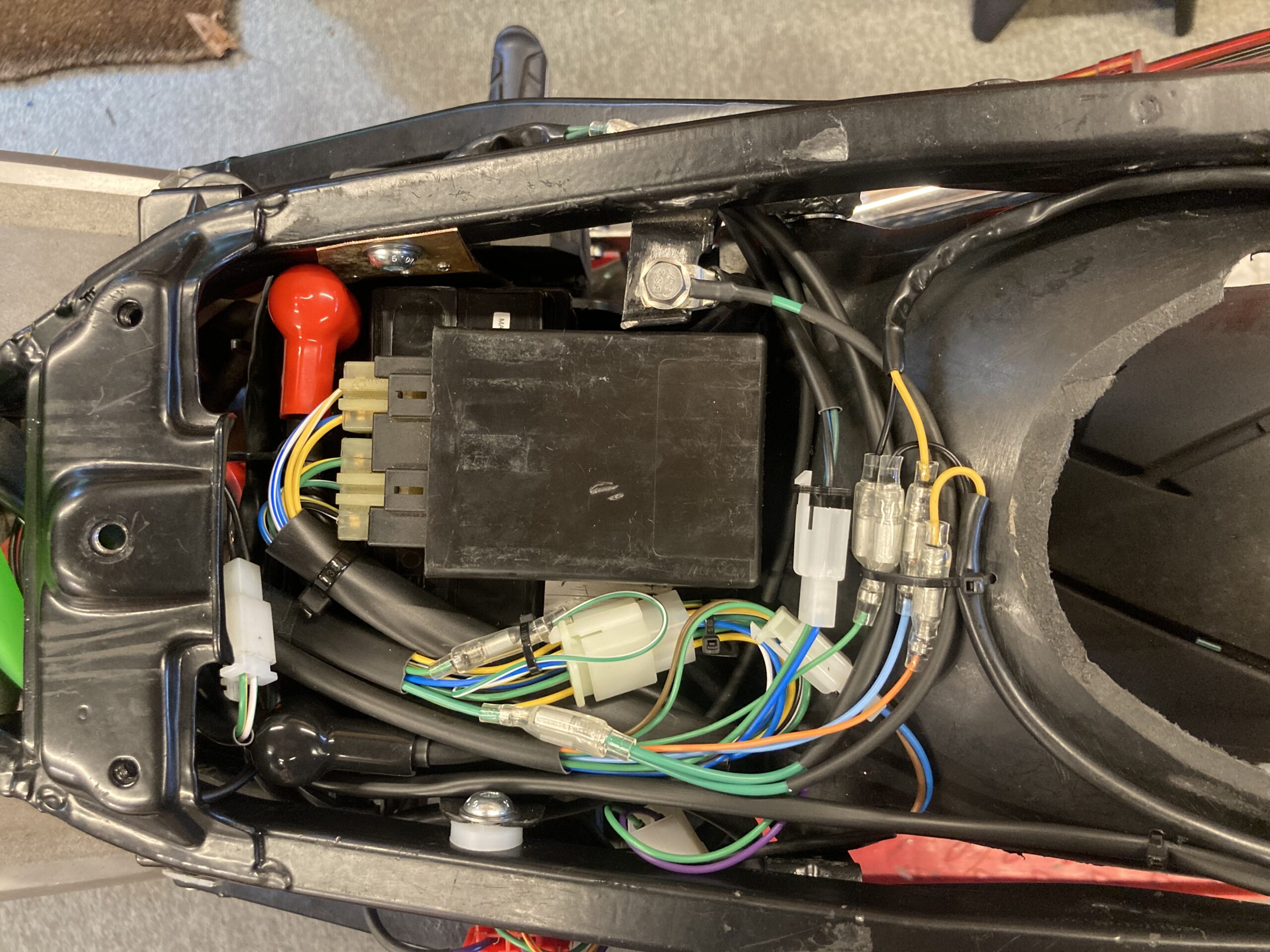

The extra sleekness of the seat unit had squished up the electrics a bit, and by the time the bike arrived at the shop it hadn’t run for three years, probably because it had been playing up even before that.

I started thinking I might be able to repair the original loom, but it had been much modified over the years. The only option (as Les had warned me) was to start again.

The big challenge was to keep most of the original Honda functionality, but cram it into a smaller space. We agreed to ditch the safety cutouts and park function, and Les had already fitted LED lights throughout. The LEDs help a lot: you can use thinner wire, which when you have 20 wires is quite a saving in space.

The best method with any custom bike is:

1) Put the original loom somewhere safe;

2) Renovate/test all the electrical components, and then mount them securely; (This is always a long process. On Les’s bike it took two-thirds of the time.)

3) Build a new loom, using the old one to show you how (for example) to get the ignition box pins right, etc. It’s also good to nick bits off.

Now we have E5 and E10 fuel, getting a long-stored bike to run again is a real nuisance. You usually have to strip the carbs and clean the pilot jets. But I tried starting Les’s bike anyway. It fired up instantly. Hondas, eh?