Julian’s Triumph 500 Metisse

This is, I think, the sixth Metisse I’ve worked on. All of them are beautifully made and a right old nightmare to convert to road spec. As Rickman built the Metisse as a racer, this is hardly surprising.

Julian is one of my most enthusiastic customers. He just loves interesting old bikes. One of them is an ex Maria Costello XR69 which you can see here.

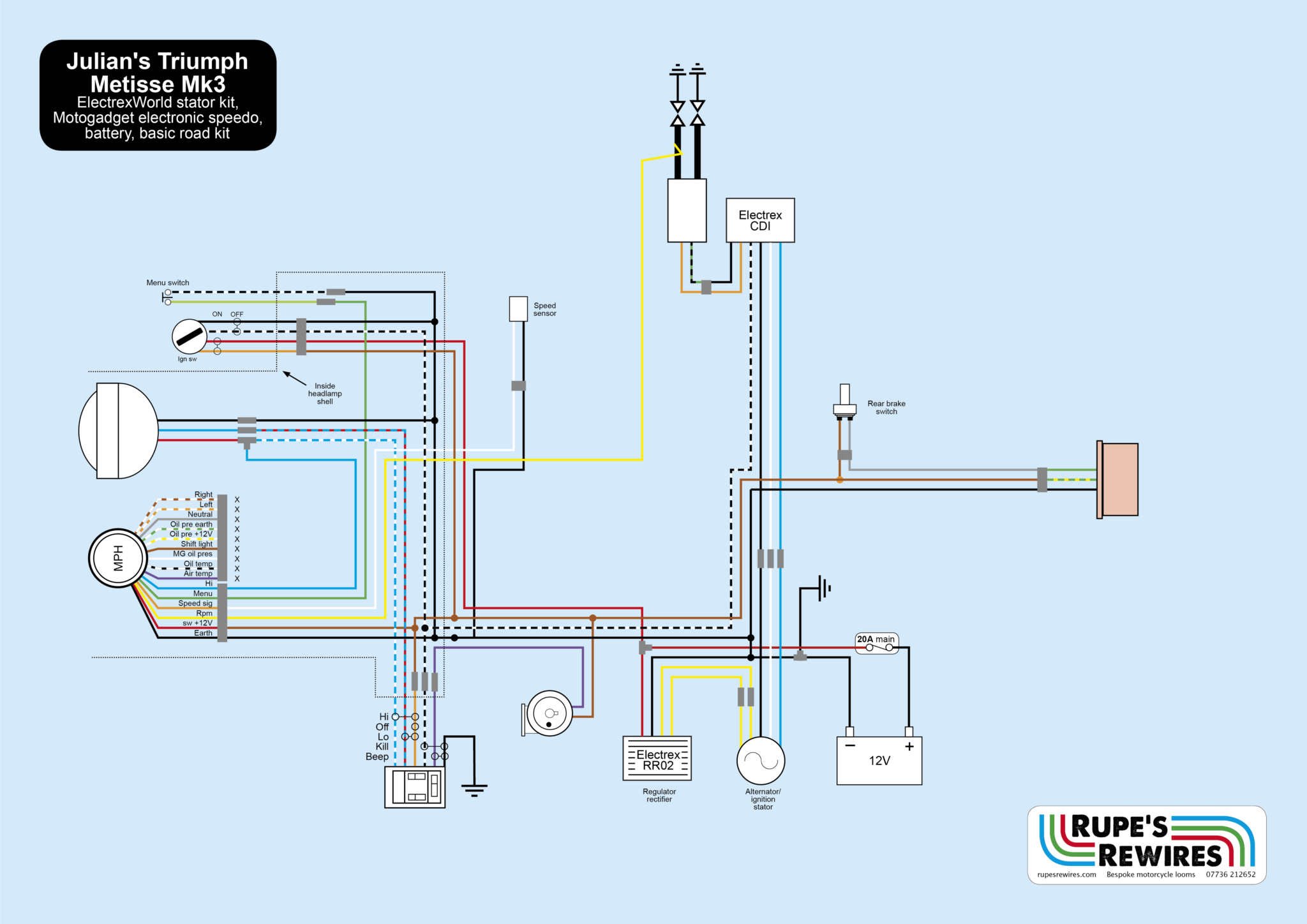

The Metisse turned up, still covered in mud from its last outing, with an ancient ignition that weighed about 4 kilos. The brief: make it into a stripped-down road bike, using the latest ElectrexWorld stator kit which provides CDI ignition and 12V charging for the lights and horn.

First job was to sort out all the stuff it was going to need: brackets (or at least mountings) for headlight, ignition switch, speedo, rear brake switch, battery, CDI unit, regulator rectifier, ignition coil. And fit a sidestand. (I know Rickman make one, that clamps to the right hand swing arm tube, but seriously?)

This kind of fabrication is way beyond me so I shipped the bike over to my old college mate Simon Martin, who has been building bike chassis for about 35 years. Not only can he make all this stuff; he blends it into the style of the bike so it looks part of the original design. Considering Rickman provide almost no mounting points for anything on their competition frames, the result is, in my and Julian’s opinion, a masterpiece.

The loom build itself is fairly simple. Julian had chosen an LED light and a fabulous Motogadget speedo. The rubber tail light just bolted onto the existing tail unit. For the hi/lo and horn switches, we agreed an old biscuit tin jobbie was the most sympathetic choice. The battery, a Motobatt 4BB, is as far as I know the smallest 12V motorcycle battery which isn’t a lithium or a wet lead/acid type. Both of which are undesirable.

Finally it was time to fit the stator kit. Except someone had built the motor as a racer, and the taper on the left end of the crank was no longer there. Which meant Julian needed a new crank! Again, not my skill set. After a long conversation we decided to get another old friend, Alan Seeley, to source a roadgoing crank and build the engine back up. More on this when it’s done…