Dave’s Yamaha YZR500 GP replica

These days, if you want to build a 500 GP replica, you can get pretty serious.

Dave’s bike uses Yamaha’s RD500 V4 motor sat in a faithful copy of a factory Yamaha frame. I’m not sure who the builder is, but it’s about as far from tig welding muppetry as you can get. A really superb piece of work.

The same goes for the suspension and wheels. You can tell, I hope, that this thing has been built really carefully and has generated a few sleepless nights.

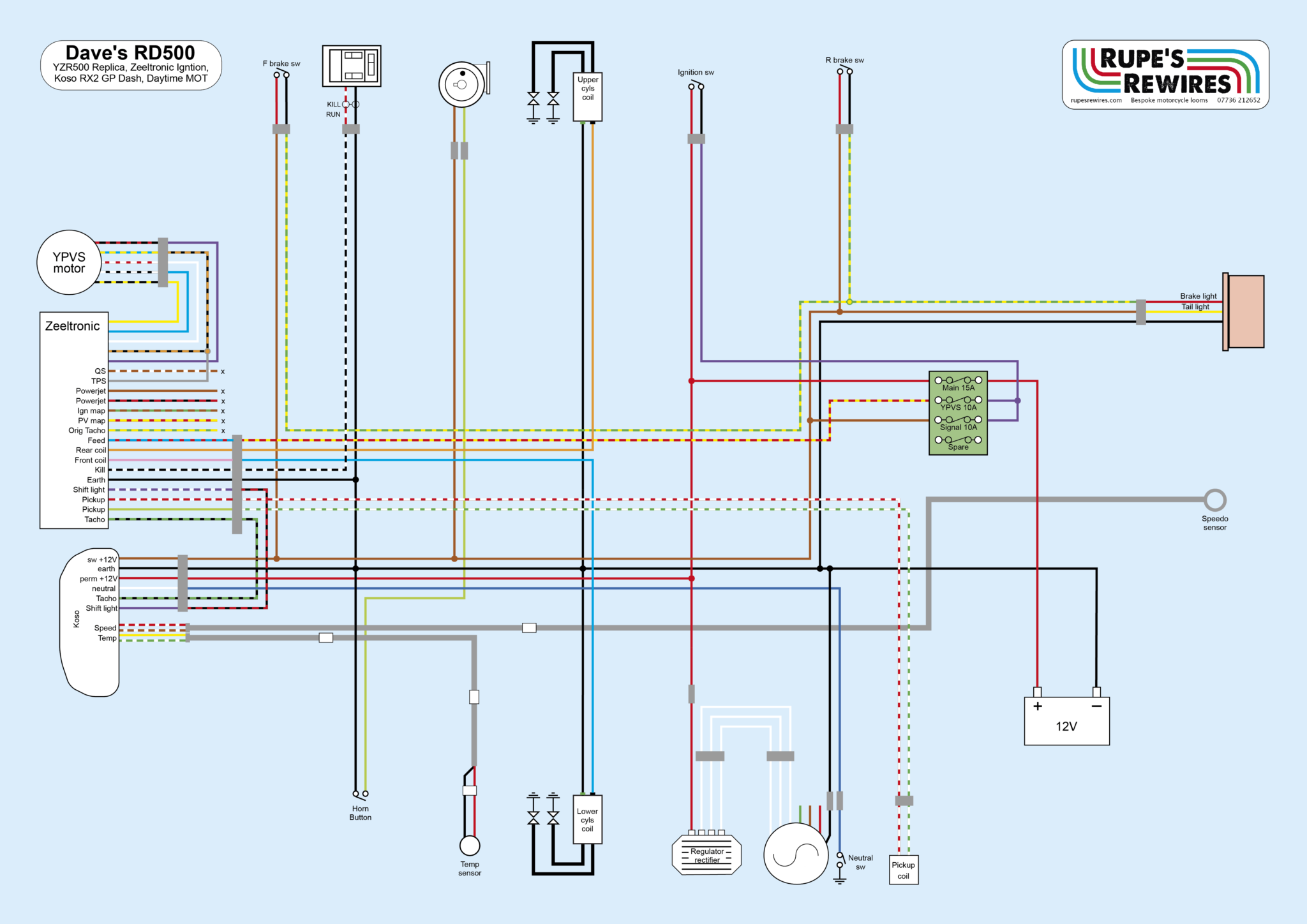

Dave had mounted all the electrical bits, and used another 500 replica on this website as a reference. The idea was daytime MOT, sensible fusing, and a Koso dash.

With my waiting list getting quite long, Dave went for a build by my apprentice Adam. We spent a lot of time discussing how to run the loom around the beam frame, because these motors create their own unique issues for the detail-conscious loom builder. The main problem is keeping stuff away from the raging heat of the rear exhausts.

Adam settled on a Y-shaped harness, with roughly equal amounts of cabling running along the inside of each frame spar. This is the hardest shape to build. You need to be accurate to within a few millimetres, which he is.

We couldn’t run the bike because there was an issue with the Zeeltronic ignition unit, but that’s now resolved and the Yam is back with its owner.

This is an incredible motorcycle that is going to provide a unique track riding experience.

This is the only part of the loom not split in two by the frame layout