Deutsch pins with heat shrink – the slimmest way to make a connection that you can break again if you need to

Dave’s 883 Sportster chop

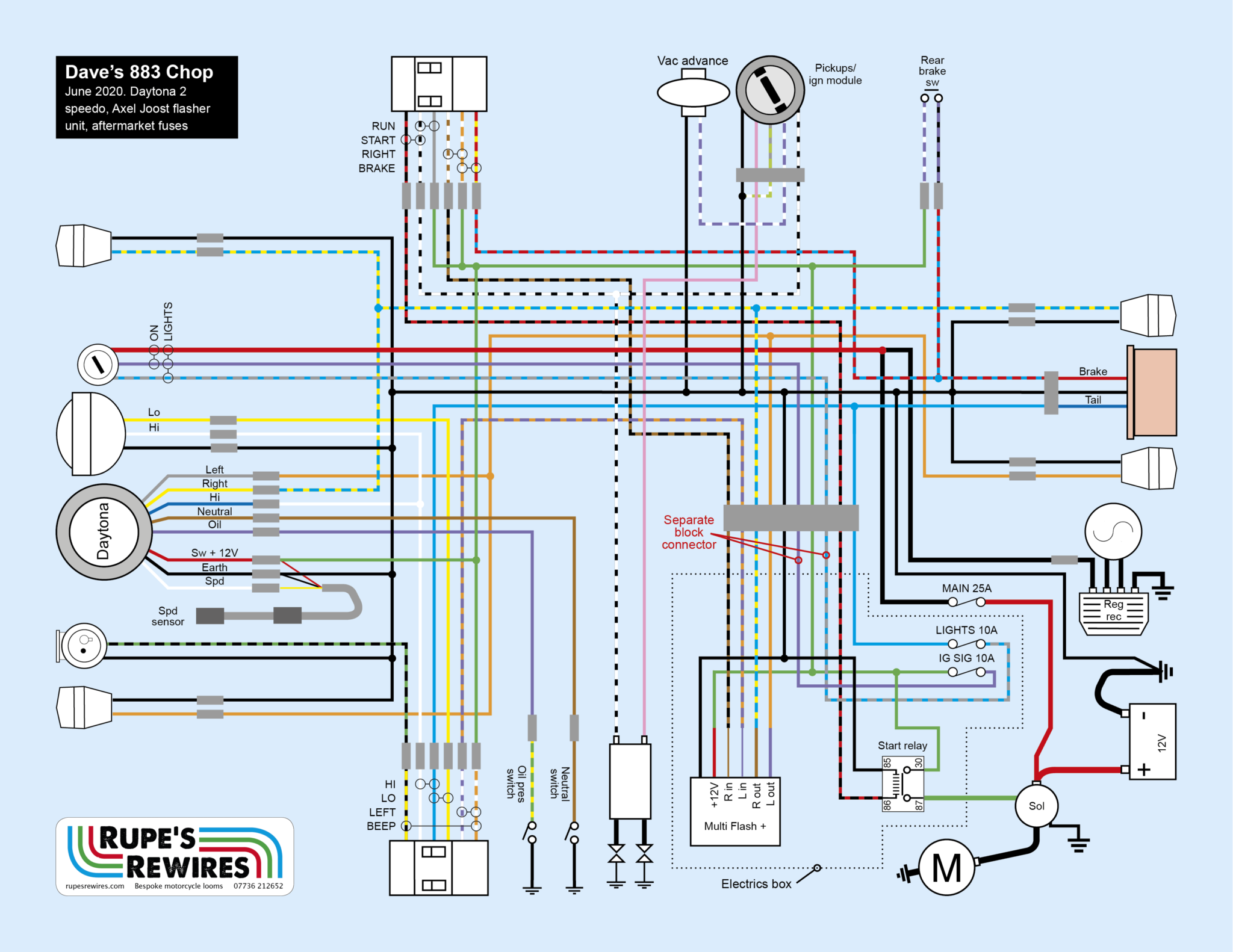

If you’re going to chop a Harley it should look meaner than a junkyard dog and twice as skinny. Dave, who owns this one, certainly thinks so. It’s a late 1990s 883 Sportster built into a Fenland Choppers frame. It arrived as a runner, but with the enormous stock loom hanging off. “Make it minimal,” was Dave’s brief.

First the bike needed a long stay in Scott’s fabrication shop next door, where it acquired brackets for the choke lever, ignition switch, lockstops, ignition coil, front indicators and Daytona speedo. Scott loves making parts that suit a bike’s look, so he really got into the groove. The rivetted brass/steel lockstop/indicator brackets are one of the best things he’s done.

There was very little room on the bike to hide electrical items or plugs, so we had to resort to extreme measures. Most of the connections under the tank use Deutsch pins with heat shrink, while the fuses, starter relay and flasher unit live in a little electrics cupboard under the seat, behind the big round oil tank.

You need a special flasher unit to operate Harley’s push-button indicator switches. (The original Harley one works fine, but it’s huge so it’s no good on a custom bike.) We went for one made by a German outfit called Axel Joost. It costs £50 from Digital Speedos, which is a lot less than Motogadget’s version.

As with all Harleys, the loom is simple – but fitting it isn’t. But it fired up first prod! The pipes are surprisingly quiet, due to having baffles inside, though the top one is very close to your right leg. I’m sure Dave will get used to it. It’s an awesome motorcycle.