The tail light relies on an earth path through it, and the rear mudguard. I revived the feed cables and soldered a decent earth onto the base plate…

…which means it can have three wires out the back. I had to drill a new hole for the earth (the black wire) but using 11 amp cable meant there was enough room for all three

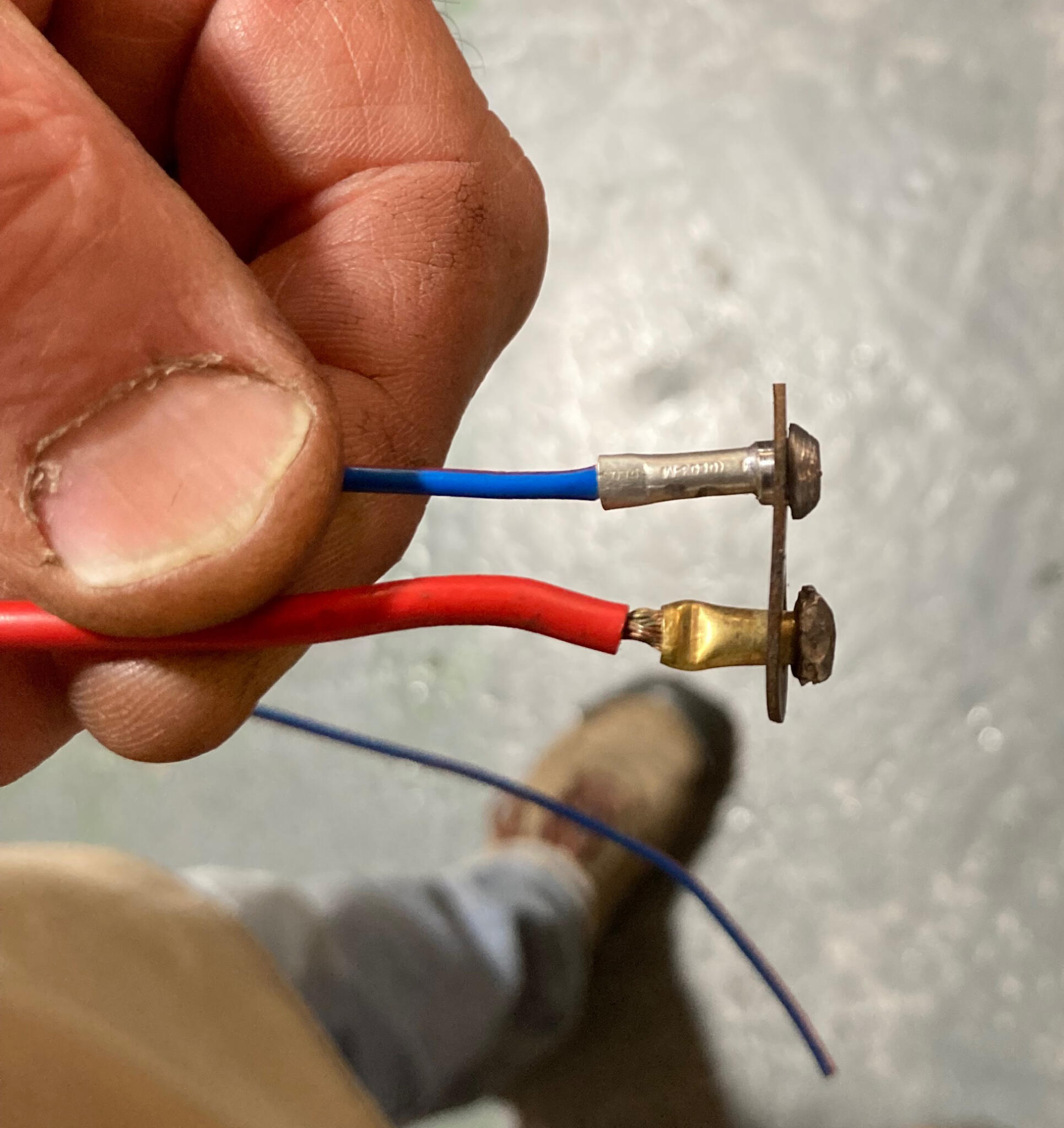

The headlight bulb contacts had already been repaired, but badly (red wire). The blue wire shows my revised contact

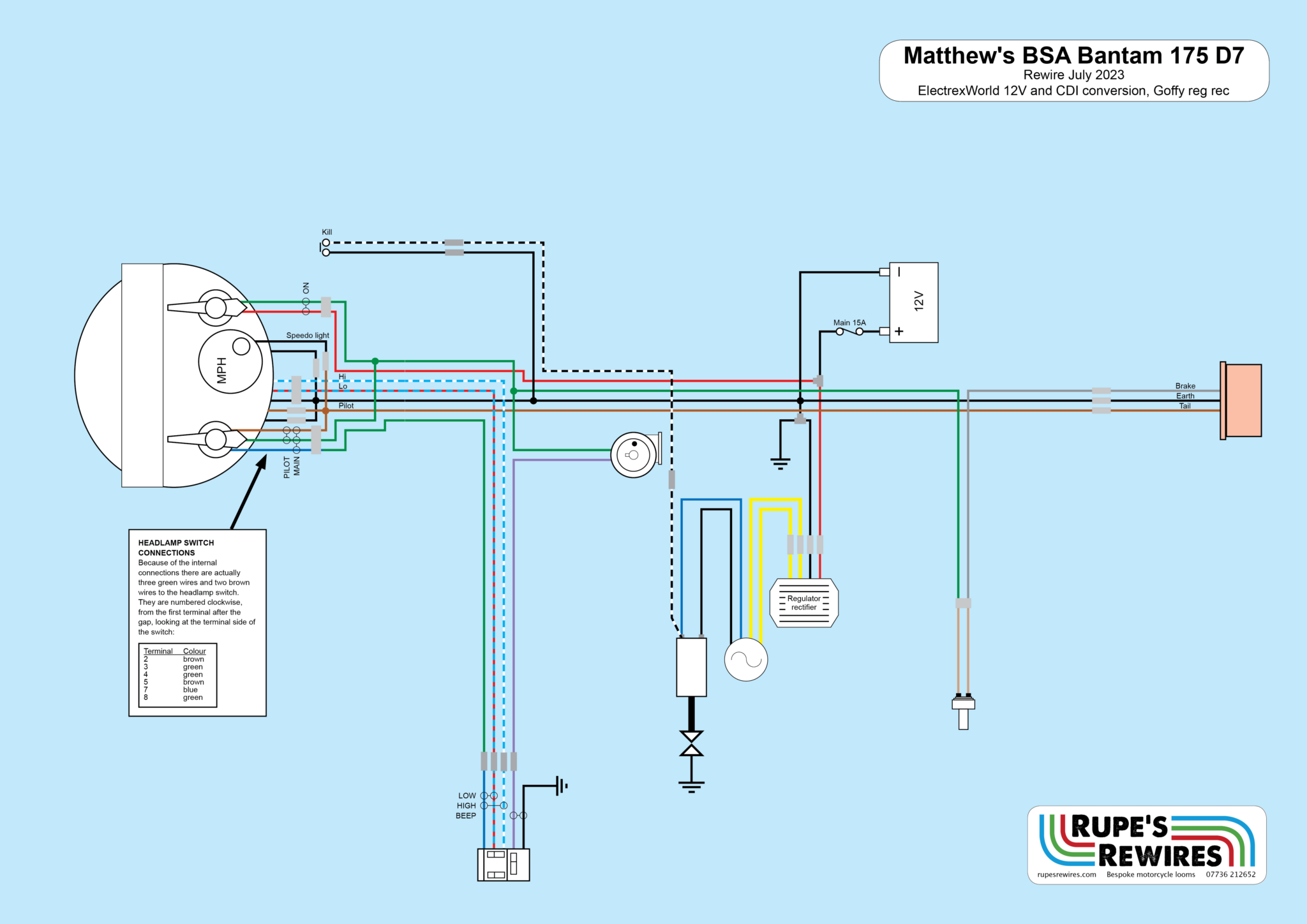

Martyn’s BSA Bantam 175 D7

Like any sensible person, Martyn wanted his Bantam to take full advantage of a new loom. This meant electronic ignition, 12 volts and a bright LED headlight.

Not only are these three upgrades a no-brainer; they also simplify the loom build enormously. But before you can build the loom you have to fit all the new stuff. And while a Bantam has lots of room inside its side panels, you need lots of time on the lathe and the fabrication bench to get everything mounted nicely.

This bike also had knackered lights. Repairing them is fun, because you need to work with what you have (or can get hold of). Above all, I like to evict any through-the-frame earths and give the bike a proper earth loom like wot any self-respecting Japanese bike has.

I ditched the original Miller switch connector plugs inside the headlight, and soldered the new cables directly to the contacts instead. Even the handlebar switch needed a big overhaul. There are loads of pics here to show you what’s involved. It’ so much more than just flopping a new loom onto the frame.

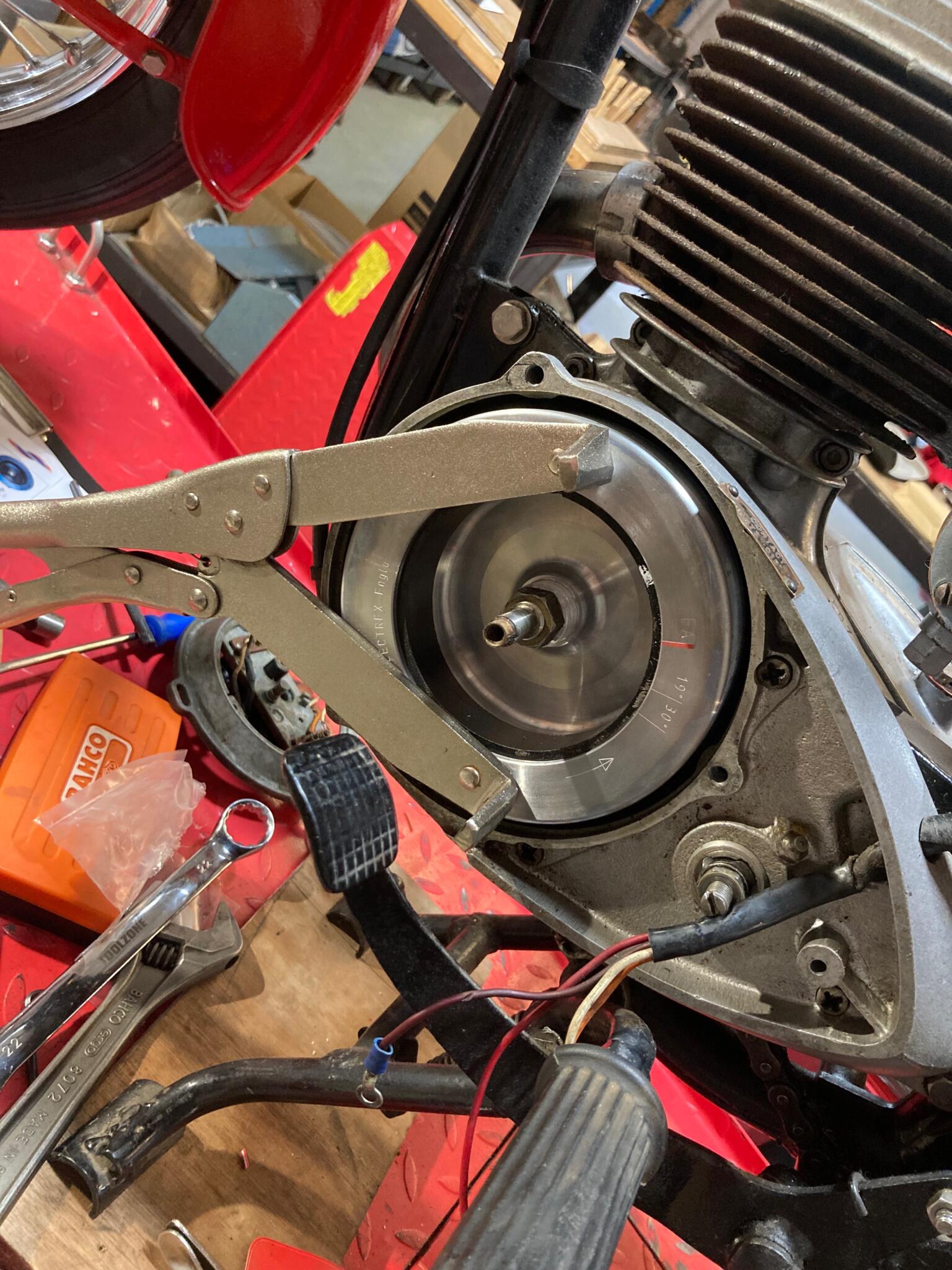

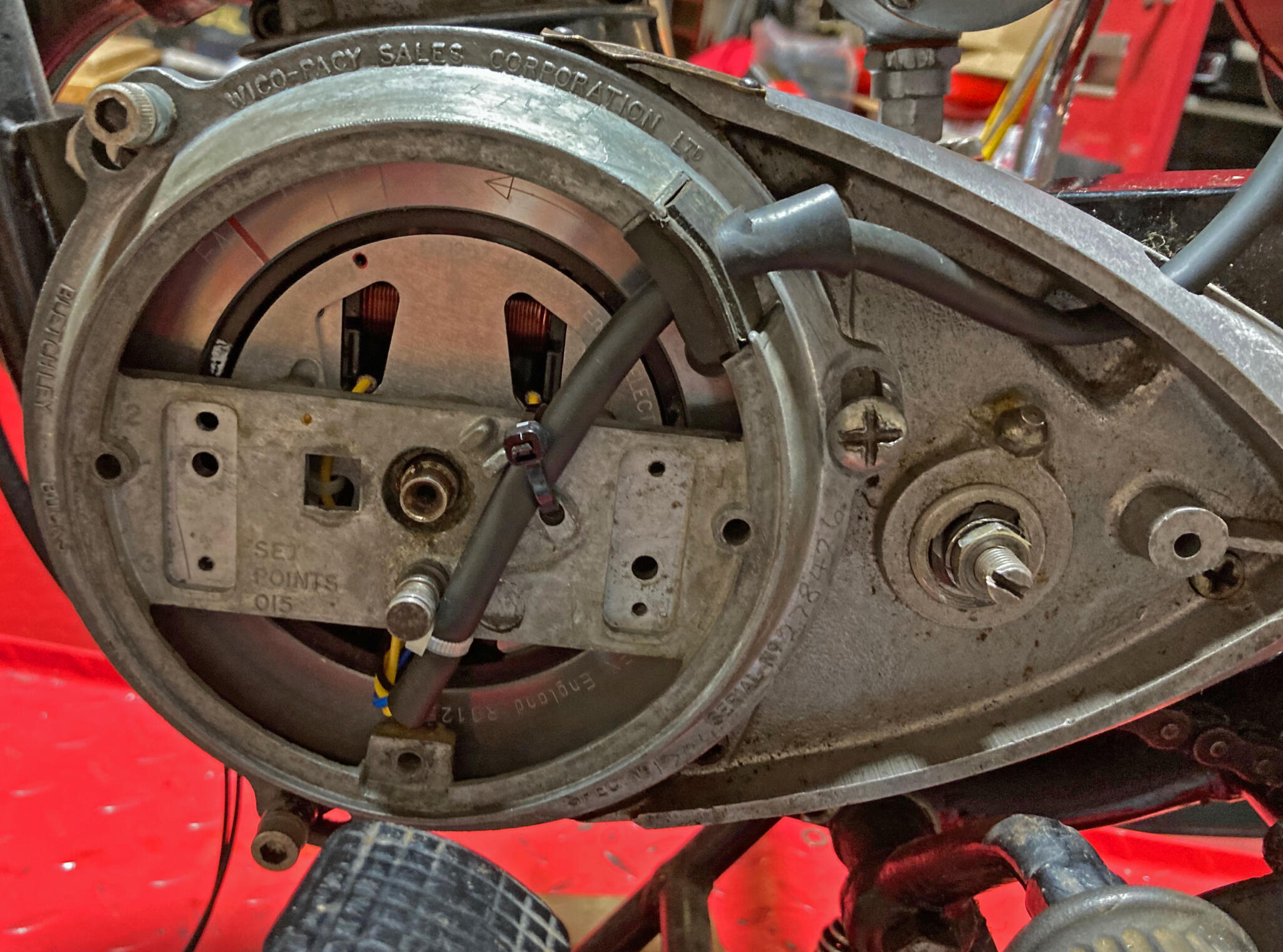

Most of the newness came from the Electrex ignition kit. It’s a complete CDI system with a charging coil for the battery, and it comes with everything you need to make a spark. I’d recommend it wholeheartedly. (The bike started first kick.)

Just as good, the original ‘switched coil’ kerfuffle, and the emergency start circuit, can waft gently out the window and float off to where they belong. In the past.

Inside the headlight are two Miller switches. One does the ignition, the other the lights. Both are wildly complicated but if you use a regulator rectifier you can simplify things a lot. The switch on the left now has two wires rather than six or seven

The main gubbins: ignition coil, battery, regulator rectifier. All three needed fitting with custom solutions. A lathe and metal folder are essential if you’re going to do it properly