Classy bike. The bulky left engine cover (this is a GTE engine) is to accommodate an electric start system. Not Ducati’s best idea

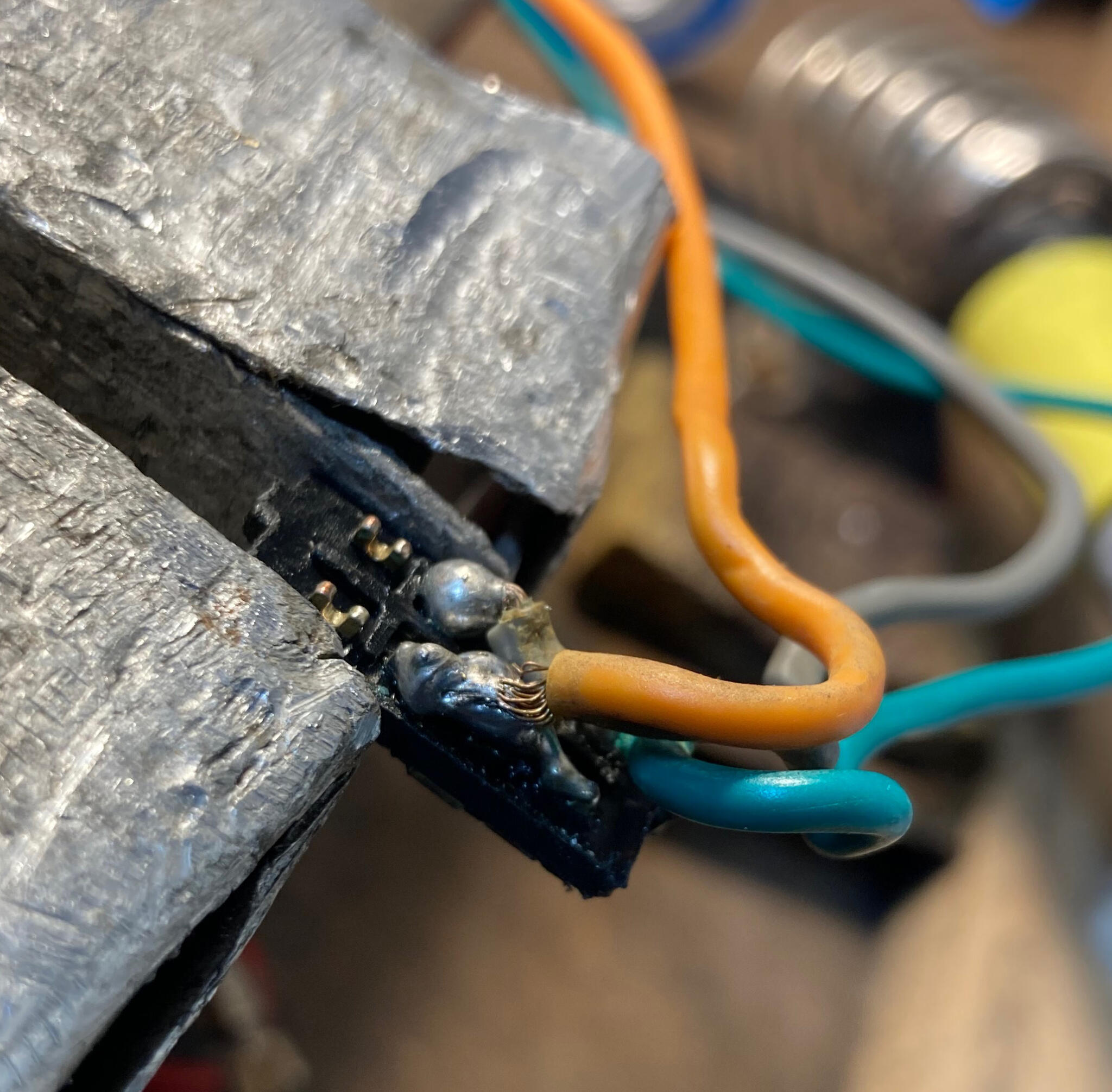

The giblets of the (brand new) aftermarket indicator switch. Crap soldering, and exposed wires. Sling or repair. I redid them

The giblets of an original indicator, repaired. All you can do is solder new wires to the relevant bits, and insulate with adhesive heat shrink

Gorgeous clocks with pinhole warning light cluster. The warning light panel was quite fragile, and uses obsolete bulbs, but four out of five of them still worked

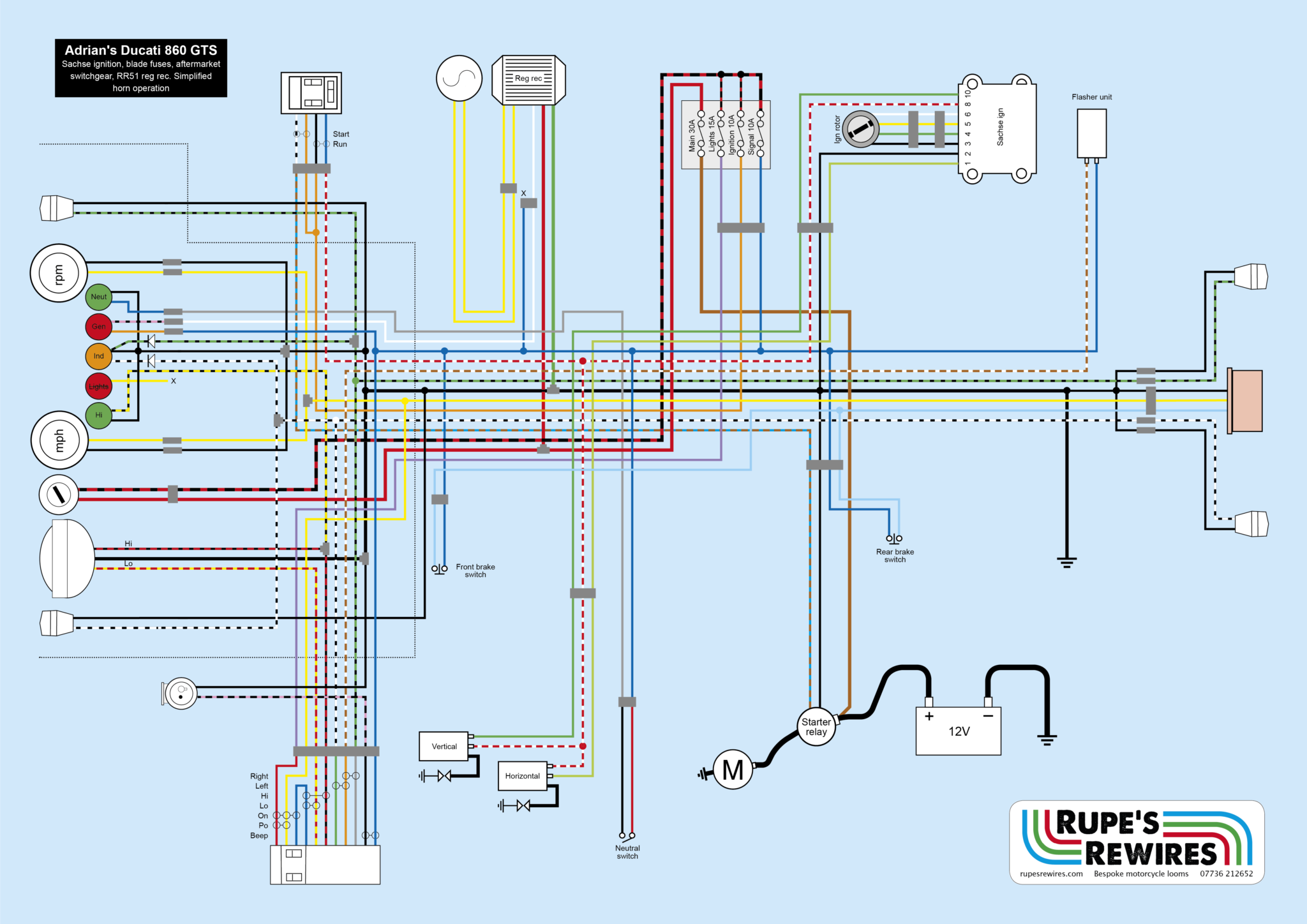

Adrian’s Ducati 860GTS

Every few months a bike comes along with a full complement of hidden gremlins. This time it was Adrian’s lovely 860GT.

It arrived hurriedly put together, after I offered him a space someone else had cancelled at short notice. The engine had been built by Ducati wizard Roy Armstrong. And the paint and running gear was properly sorted. The lights, indicators and other electricals were in a box.

You can’t build a loom until everything it feeds is screwed on, in the right place. Cue a two-day festival of making brackets and spacers, repairing fragile or neglected or plain badly-made things, and much tea-powered head scratching. Eventually everything was on, and the loom could be built.

Then came the ignition. Made by Sachse, it’s the doyenne of Ducati bevel rebuilds. I’d already fitted one to another GT, with no trouble at all.

The only slight catch with Sachse is that the pickups live on the crank, behind the clutch and the flywheel, and surrounded by several litres of oil. So you’d better set it up right, because alterations are not exactly a five-minute job.

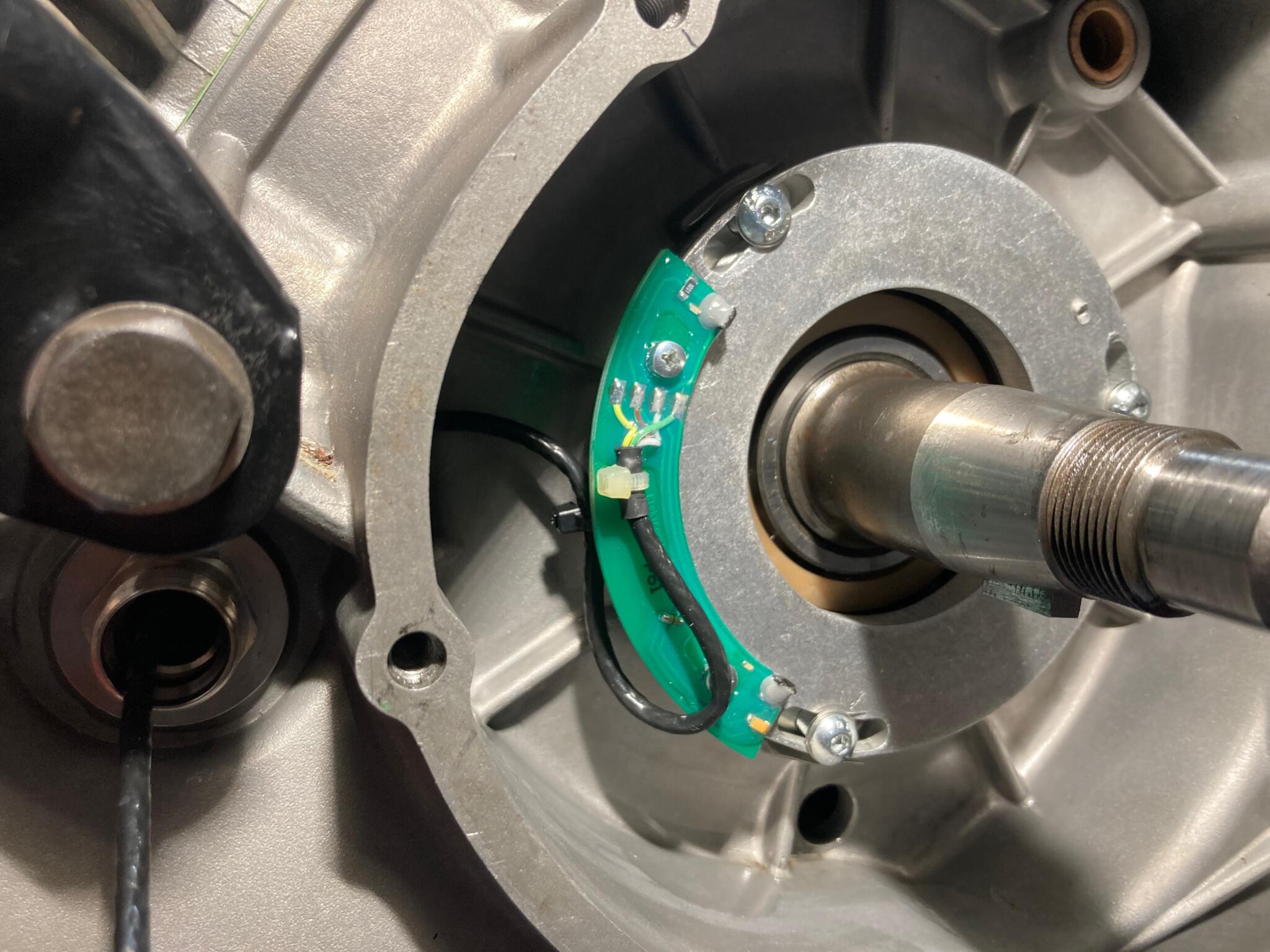

The pickups sit on a backplate which screws into a circular recess on the crankcase. This recess can vary in size, depending how much lunchtime chianti the machine operator had consumed in 1972. Sachse therefore size the trigger backplate to fit the smallest recess they’ve encountered. Unfortunately our recess turned out to provide an exceptionally baggy fit. A few crank rotations were enough to create pickup-to-rotor contact, rapidly followed by pickup death.

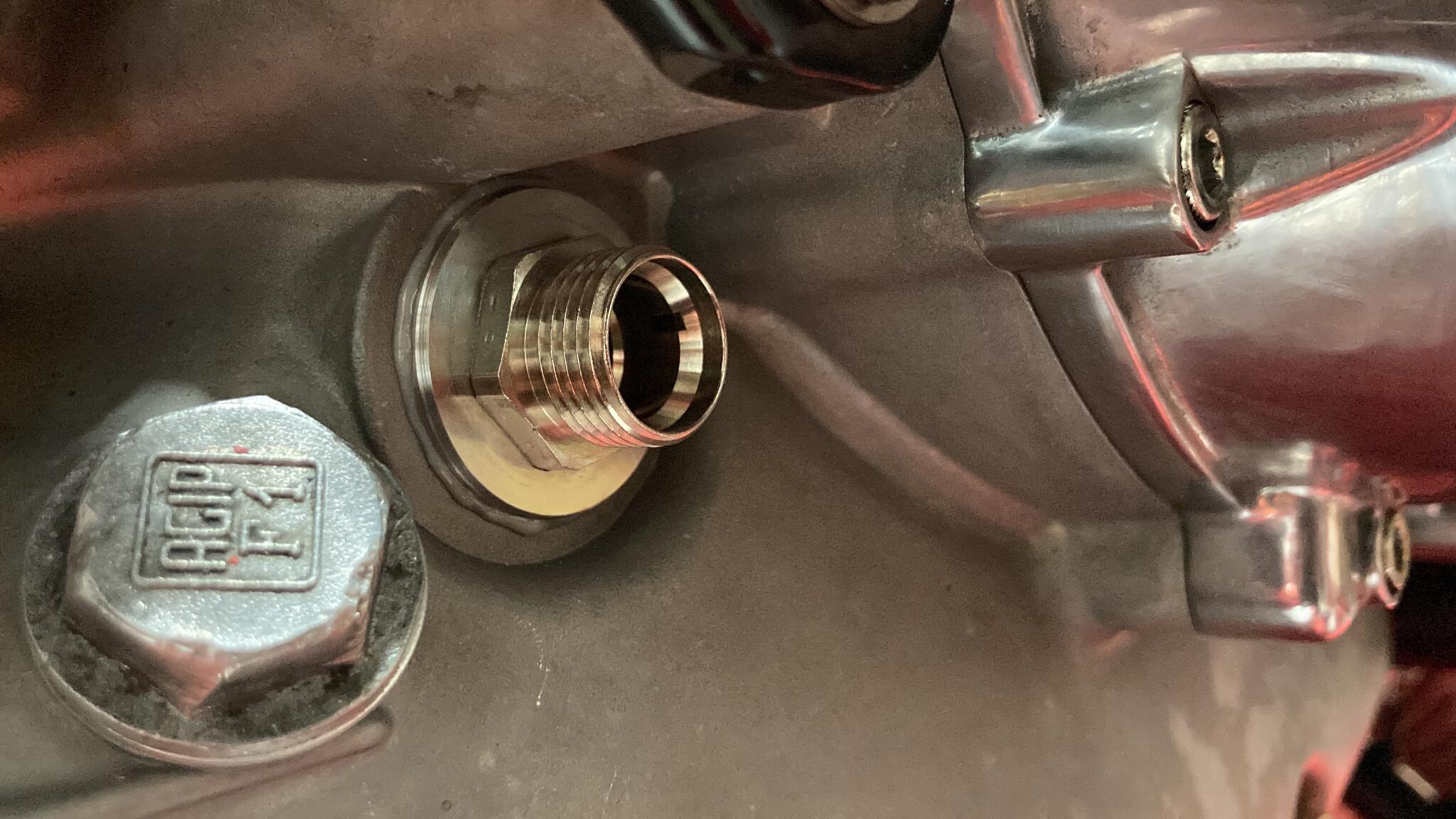

I guess I should also mention the gland carrier that takes the pickup wires out of the engine (it needed machining down to fit). And the pickup rotor which screws to the inside of the flywheel (it needed a custom spacer making up, so the magnets lined up with the pickups). And the pickup wire, which rubbed on the sharp inner edge of the flywheel.

Discovering all these foibles involves several stages of laborious building-up with a torque wrench and tab washer, each of them being (you hope) the last – followed by stripping down again with a stroppy rotor puller. What larks.

Marco at Sachse was very reasonable, and sent another pickup. This time, to take up the baggy backplate fit, I made some shims out of a can of cheap lager which my friend Andrew had been drinking. That did the trick: pickup-to-rotor clearance was ideal. Flushed with success, I drilled the backplate so I could cable-tie the pickup wires out of the way.

I should stress that Sachse is a very high quality and thoughtfully-designed ignition system. It’s just that Ducati bevels varied a lot, and you need to check the issues above. The quality of the system became apparent when the bike fired first kick, within about an inch of the kickstart beginning to move. You don’t see that every day. Especially on a bevel.

But the bike still wasn’t finished with us. The battery was charging at 17+ volts. On a brand new regulator rectifer! Adrian brought along another, older one, and this time the system stopped at 15 volts. A shade high still, but it was regulating the voltage. Job done.

Adrian remained very patient throughout all this. He’s is planning to ride the bike on two long trips this summer. I hope he will send some postcard pics.

The shiny thing is a gland carrier for the ignition pickup wires. To make it fit we had to machine it down, bin its o-ring, and glue it in with Araldite

This is the flywheel and primary drive. Notice how Ducati’s early electric start has gnashed the flywheel teeth. Adrian will not be using this feature

The inside of the flywheel, with the new rotor screwed in place. Our custom spacer is hidden under the rotor