Paul’s Ducati 888/916 track bike

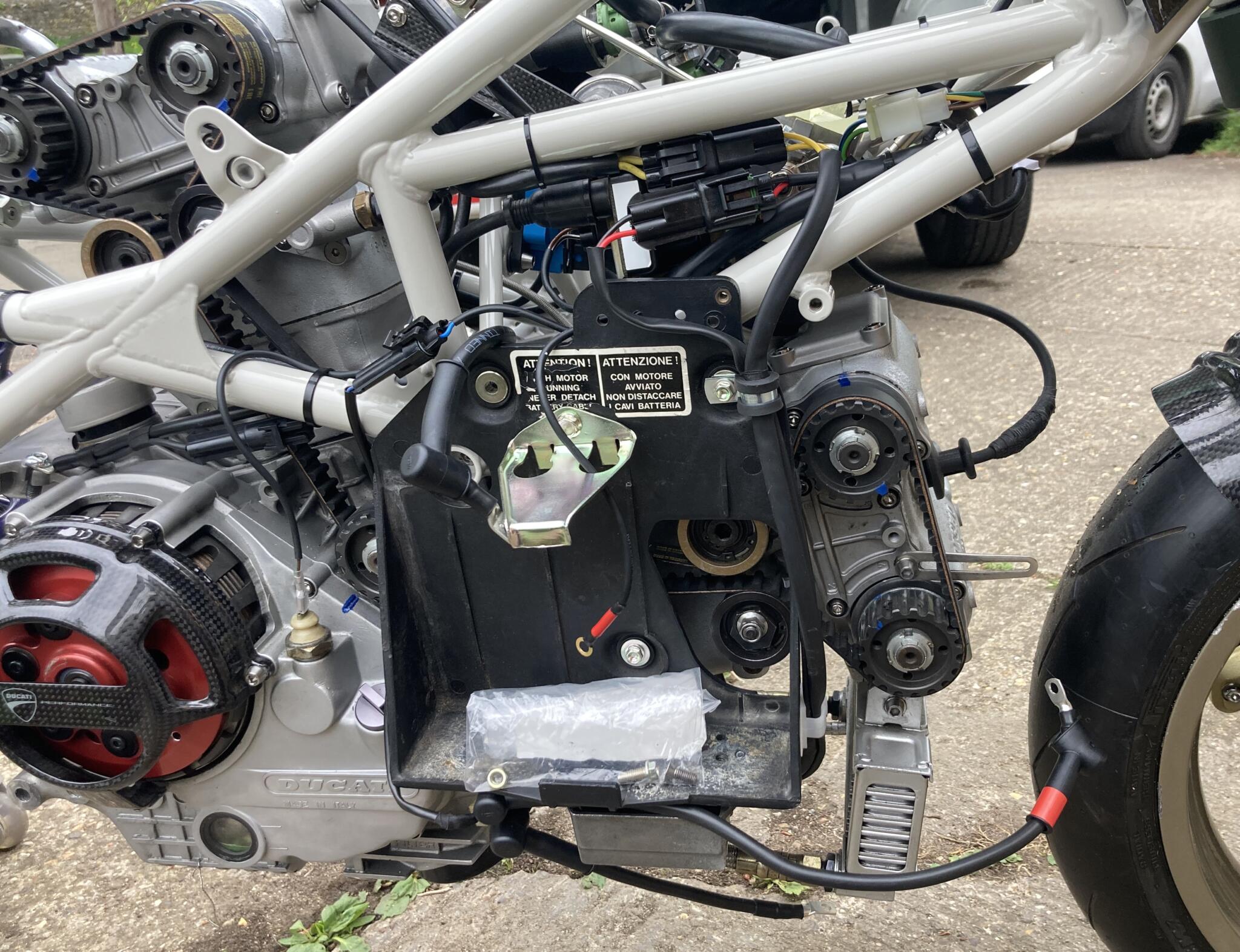

With several 1980s/90s Ducatis in his garage, it’s safe to say Paul has Ducati disease. This is a bike he’s built for road and track use, and possibly even for the Classic TT if he can find a suitable rider.

It’s got all the mods developed in WSB and more recently at the Classic TT: longer swing arm and shorter yokes to shift the weight forward as much as poss; some top notch suspension (by K Tech); period front brake calipers; light wheels; lots of carbon; and a tuned 916 motor.

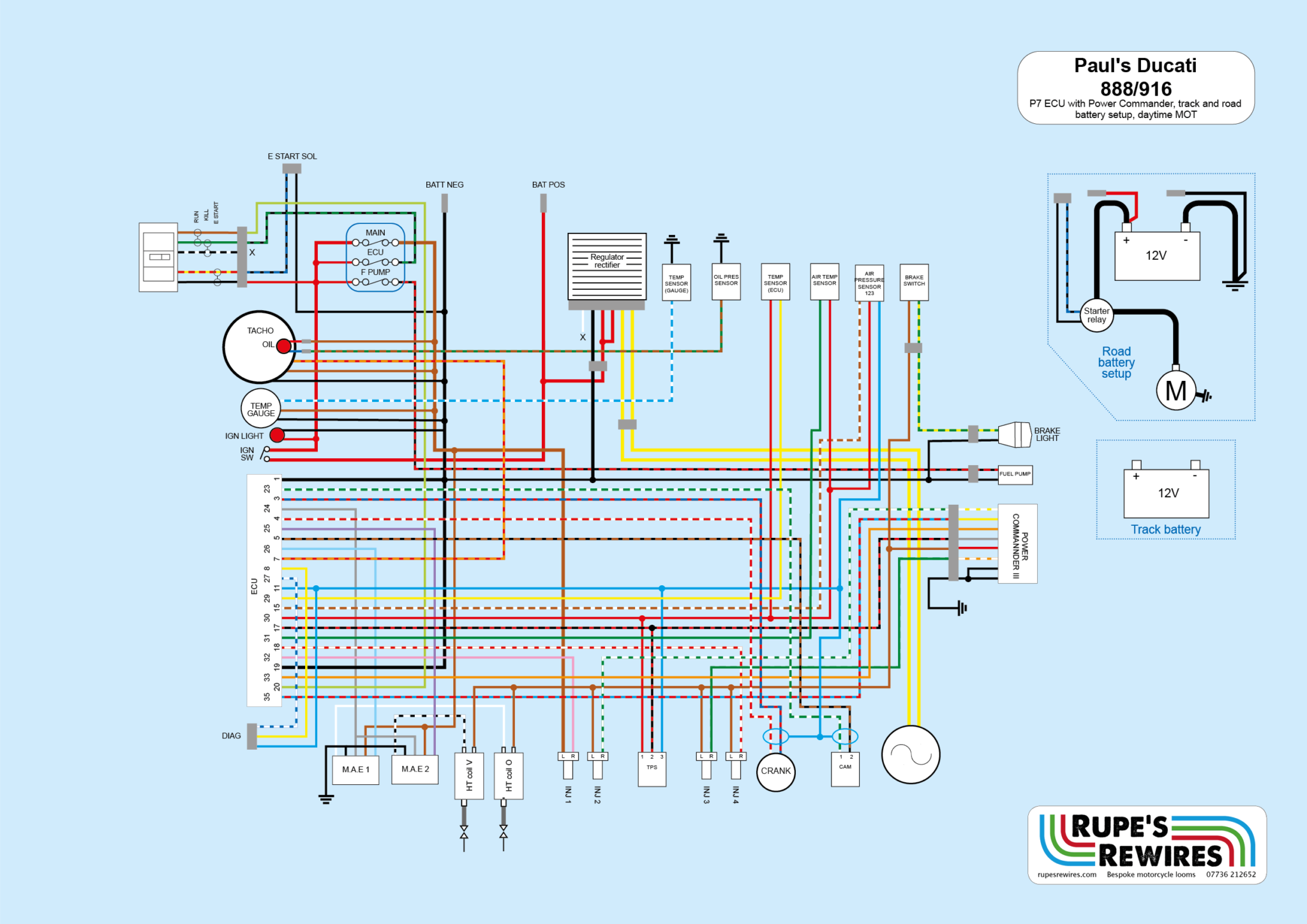

When Paul rang to organise a loom build the order book was rather full, so he took the option of a swifter job by my apprentice Adam. Adam is really an apprentice at The Splined Hub where I rent a corner, and makes up fuel injection looms for E Types. But he builds bike looms in his spare time, and does a very nice job. His diagrams look a bit different from mine, but the electrons don’t care.

Despite not having been born when these bikes were winning world championships, Adam is more determined than me, and spent hours identifying the ECU and the tacho. Both these items were important because they affect how and what you build.

Paul wanted the option to fit and remove a starter motor, plus the heavy battery needed to turn it, and the solenoid. So Adam’s first job was to figure out how to do that with the minimum hassle. Paul’s idea is to run a light bike for track use, and chug around on the road on sunny days with easy starting.

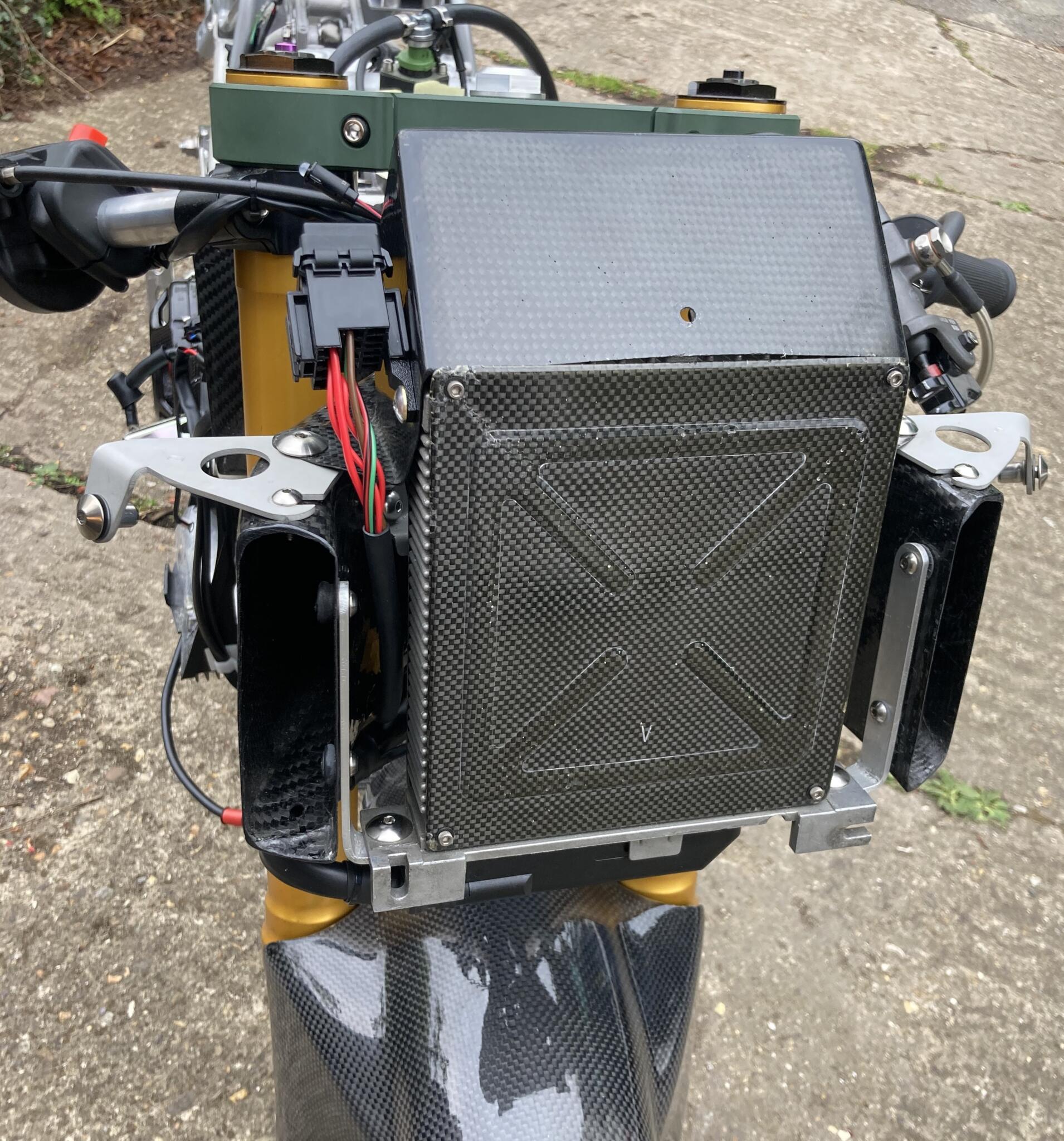

One of the big things you can achieve with a scratch-built loom when a Power Commander is involved is to bin all the messy connectors that plug a PC into a standard loom. So it gets a lot neater. We also found a good place to put it: under the seat.

We couldn’t run the motor when the loom was built because Paul had a bit more work to do first. But it’s a fabulous motorcycle, dripping with history and class.