Bullet connectors on the left frame tube are pretty invisible on the finished bike, and allow tail light and brake switch to be individually removable

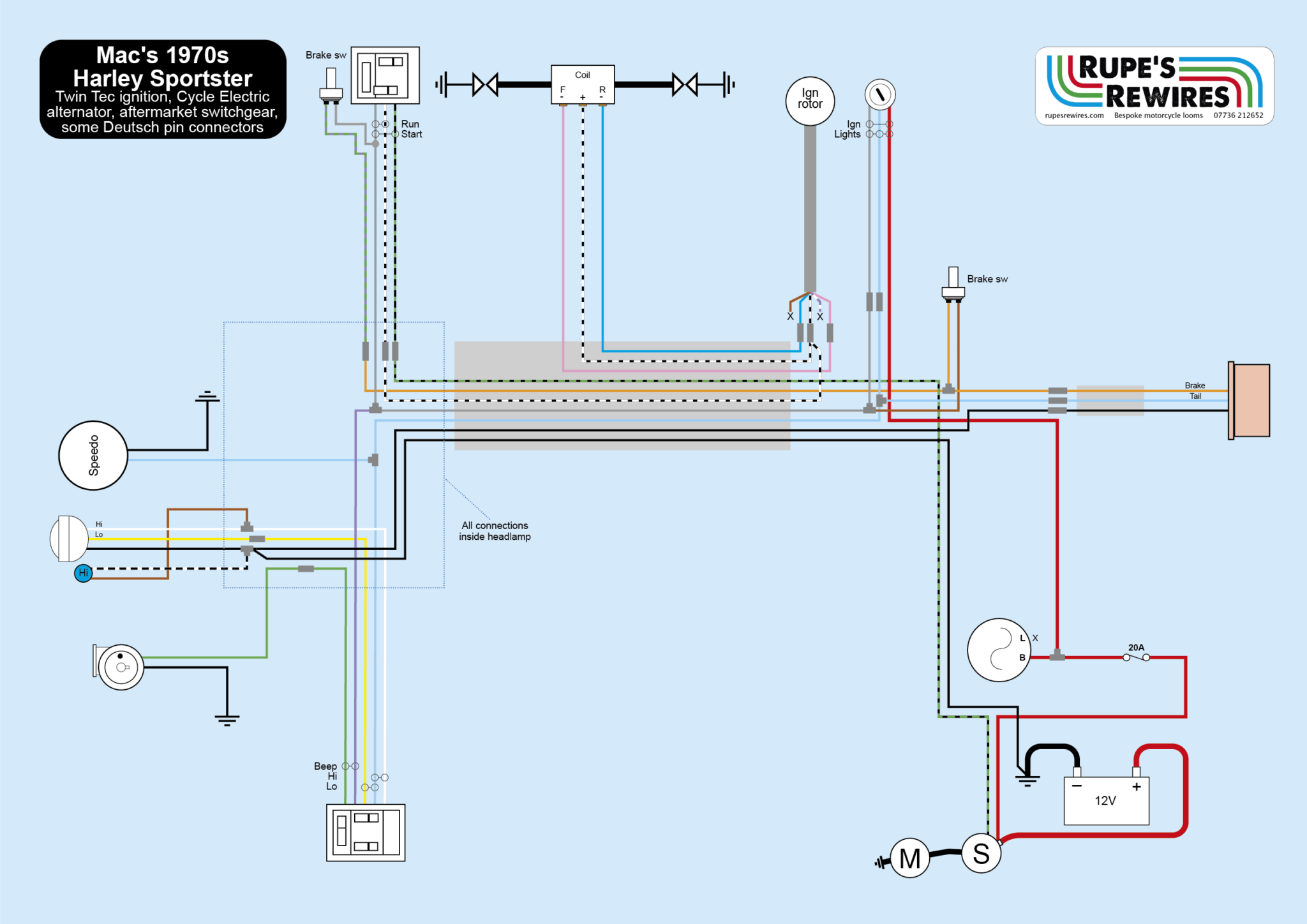

Mac’s 1975 Harley Sportster hardtail

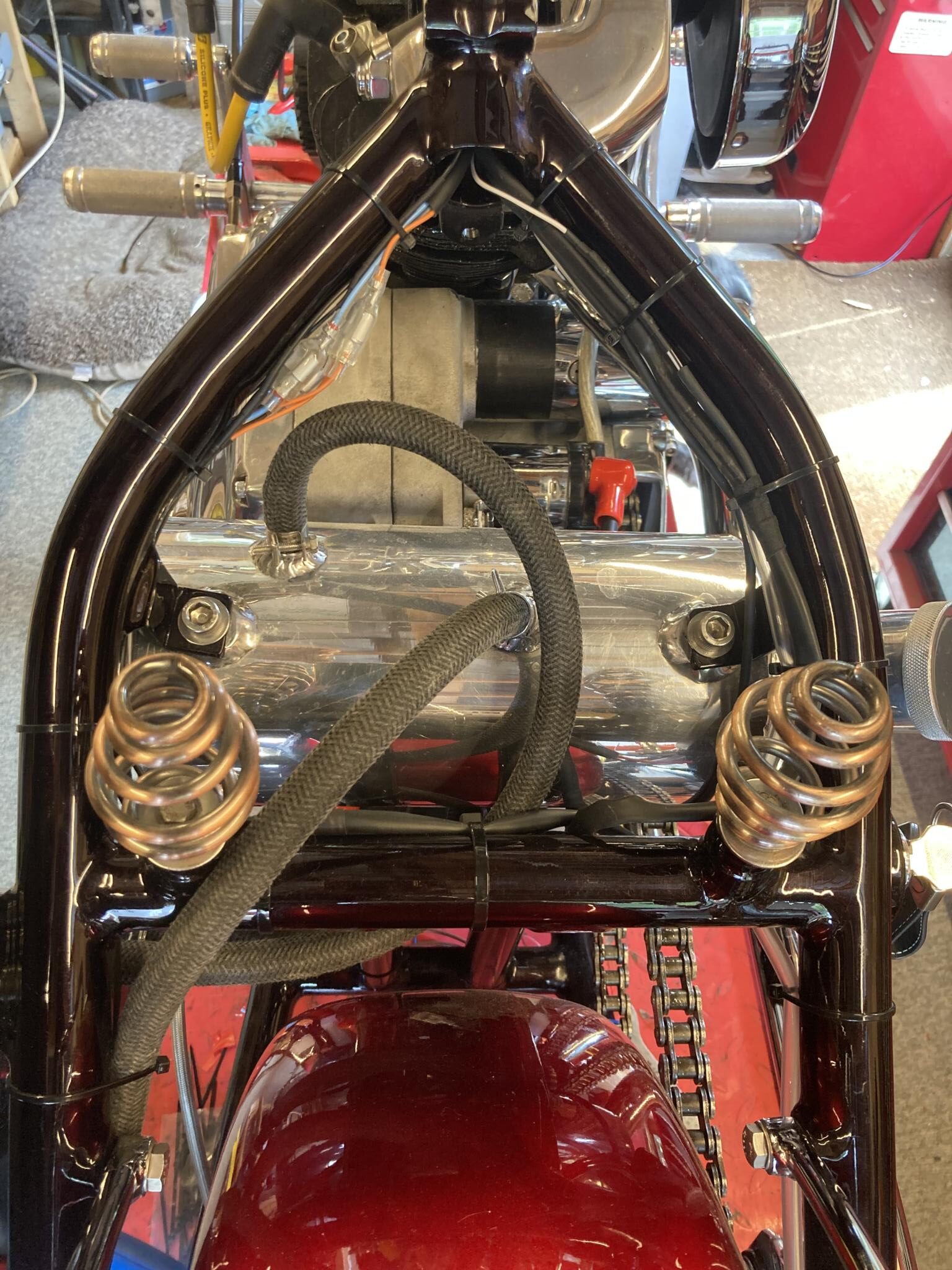

This bike has had three owners in 20 years, and Mac is the first one to have it finished. “It’s probably taken me 14 years to get it like this,” he says.

It’s an old Sportster motor with a beautifully-welded hardtail frame and some very high quality paint. With any bike like this, the game is to make the wiring as unobtrusive as possible. This can sometimes feel like a crazy objective to work with, because stripped-down choppers have almost nowhere to hide any components. (Under the tank, you say? No chance!)

A lot of people just solder everything together and wrap it in tape or heat shrink. But if the bike falls over and you have to replace, say, the tail light, you have to break into the loom and bodge a repair.

I prefer to make all the components individually removable. With a bit of cunning, you can make very subtle breakable joins using Deutsch pins. It’s a technique I haven’t used for a couple of years: crimp on Deutsch pins, and instead of fitting them in a Deutsch housing you just heat shrink each pin pair.

It’s easier to do on some components than others, so I used a few Japanese bullets where I thought I could get away with it. Otherwise you can spend hours on something most folk won’t notice.

Mac was pretty pleased with the result, even though I couldn’t fire the motor up for him. The battery had been in the bike so long it was kaput. He’s ordering a new one and looking forward to riding it to a few custom shows.