Andy’s Suzuki GT550L

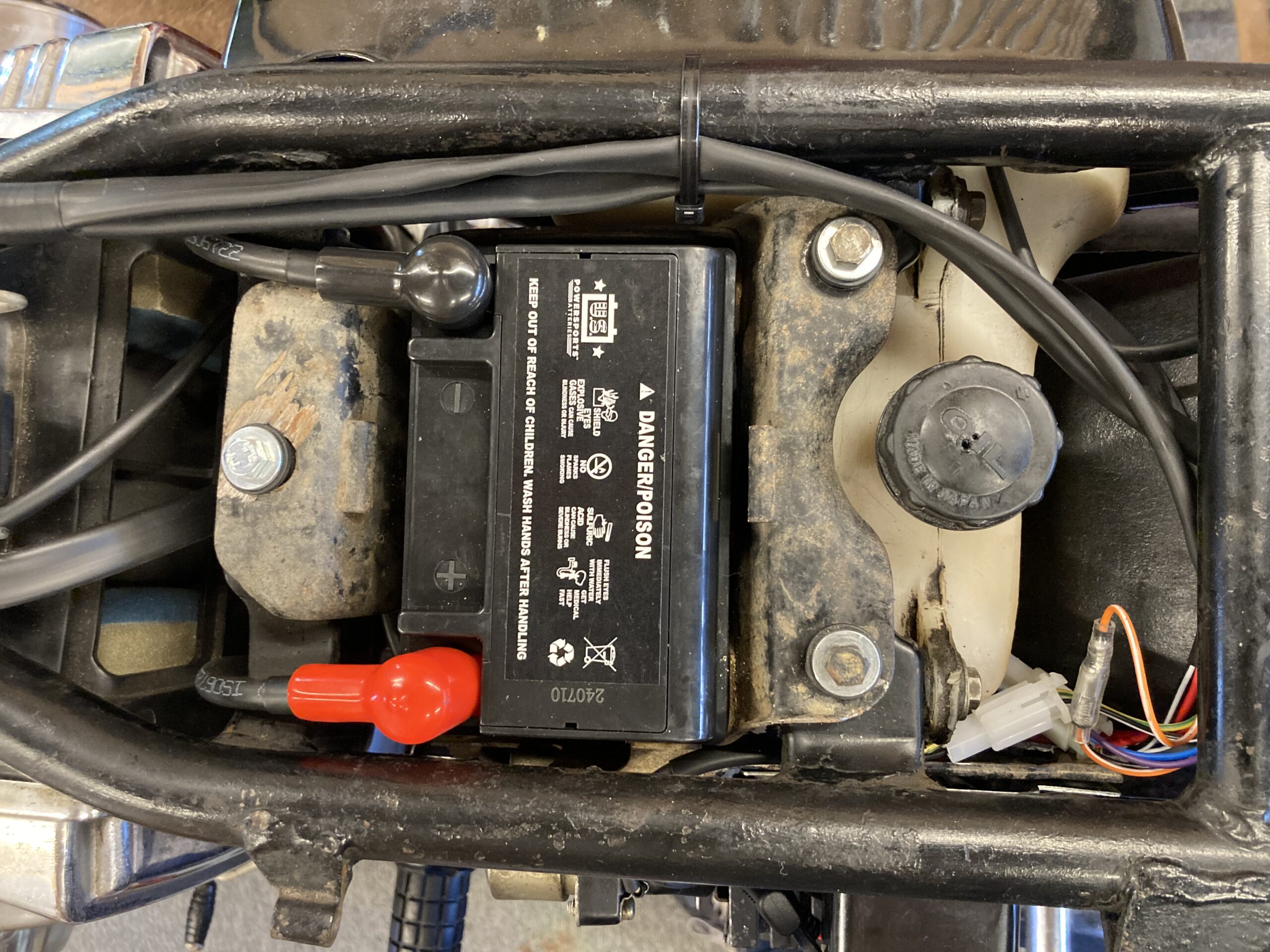

Unlike many bikes that arrive at the RR workshop, Andy’s GT was very much a runner. He’d bought it in lockdown as a Canadian import, and done 12,000 miles on it since.

But electrically it was staggering about like a man who has walked into a gently swinging demolition ball. And Andy knew it.

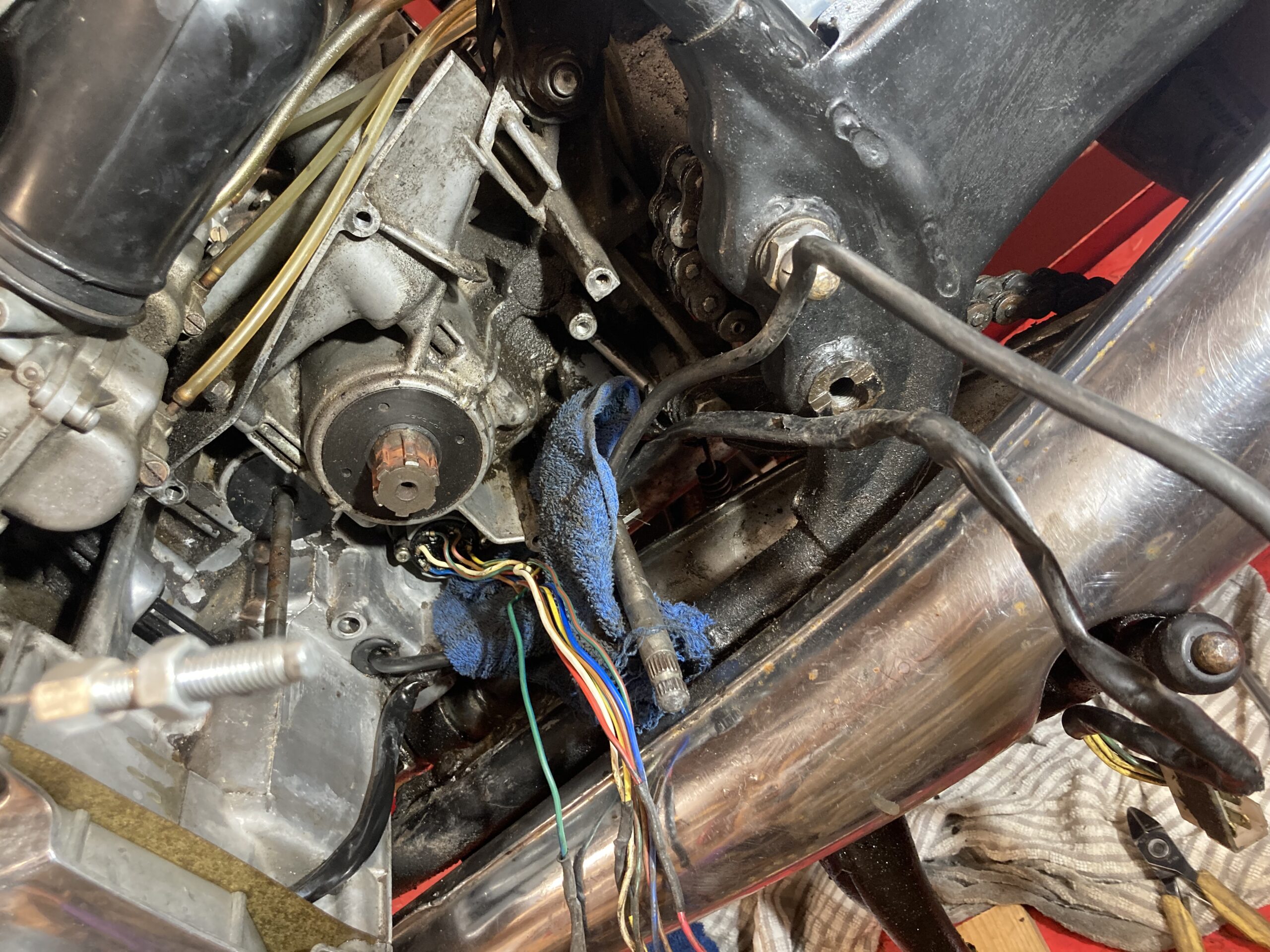

As with almost any old bike, the GT’s electrical components revealed a past of wildly optimistic bodges. Every component, except the front brake switch and tail light, needed repairing or modifying. It takes a long, long time, but it’s all good fun. And eventually, you get to a point where you can start building the actual wiring loom.

I had a good go at getting the digital gear indicator display working again, but powering it up showed that only one element in the display was still working. Andy is going to hunt around for a replacement, but it may be a while. I made sure any new display could plug straight in. I also labelled the sensor wire colours, in case a different sensor needed its pins swapping around.

The wires came together well, and starting the motor afterwards proved Andy’s experience: it fired up right away, ran smoothly, and sounded gorgeous. The smoke billowed everywhere. Years ago, that kind of thing was just normal!

Andy had been looking for someone experienced with old bikes to give the GT a service and general check. Fortunately, I could oblige: just up the road is Rupe Farnsworth – builder and fettler of many a motor sickle, including some of my BSA A65. Once it’s been through both our workshops it should be ready for many more happy summers.