Triumph thought it would be a good idea to stick the dash in the tank. It looks nice but the original wiring is a nightmare

Here’s my solution: put all the connections on one plug to make it easier to deal with

Here’s my solution: put all the connections on one plug to make it easier to deal with

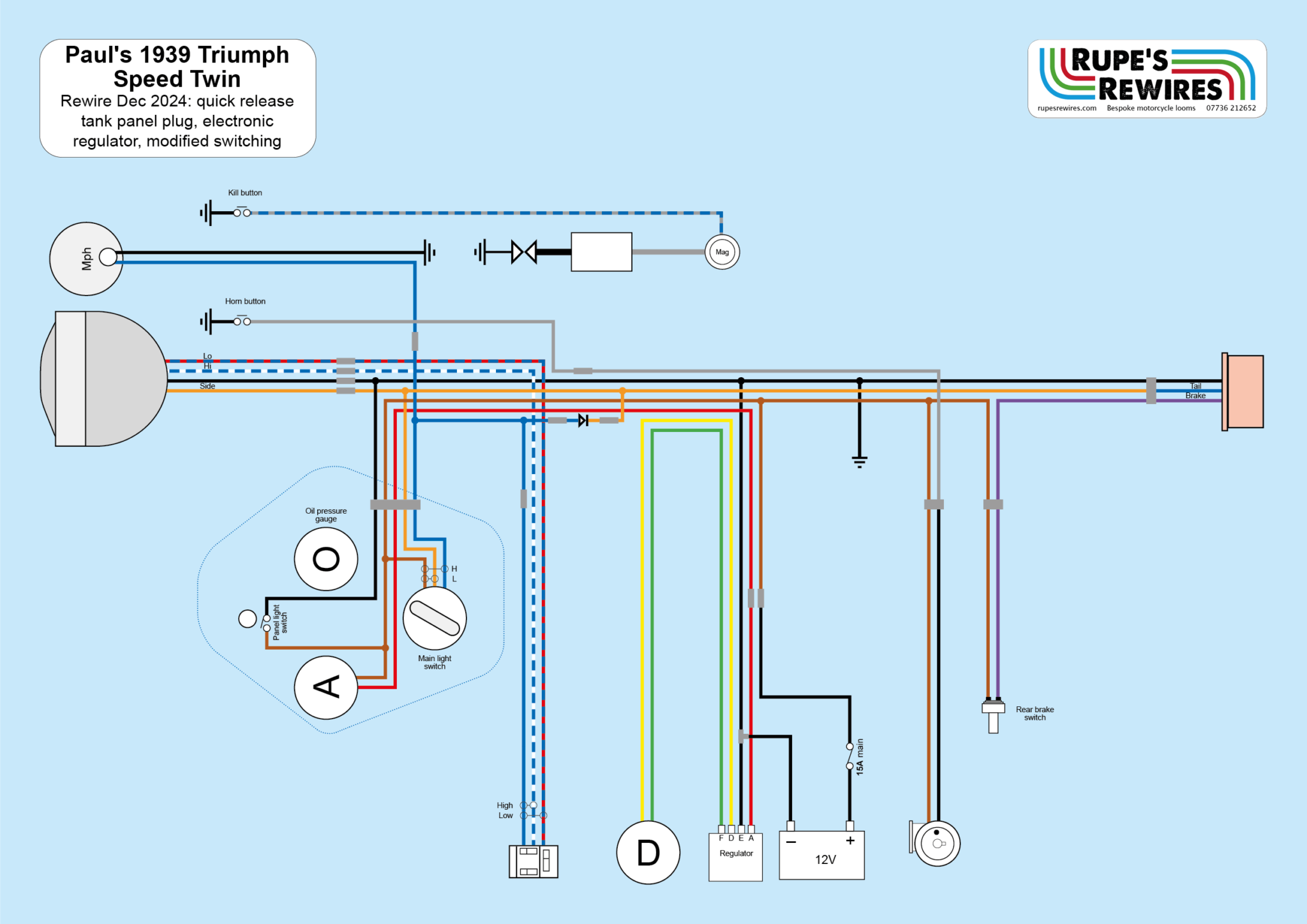

Paul’s 1939 Triumph Speed Twin

I frequently claim in these reports that there is absolutely no relation between electrical simplicity and the real-life complexity of the job. Paul’s lovely Speed Twin is further proof.

It’s just got a headlight, a pilot light, a tail and brake light, and a horn. Plus an ammeter. And a speedo light. How hard can it be?

Actually, pretty hard. For at least seven hilarious reasons.

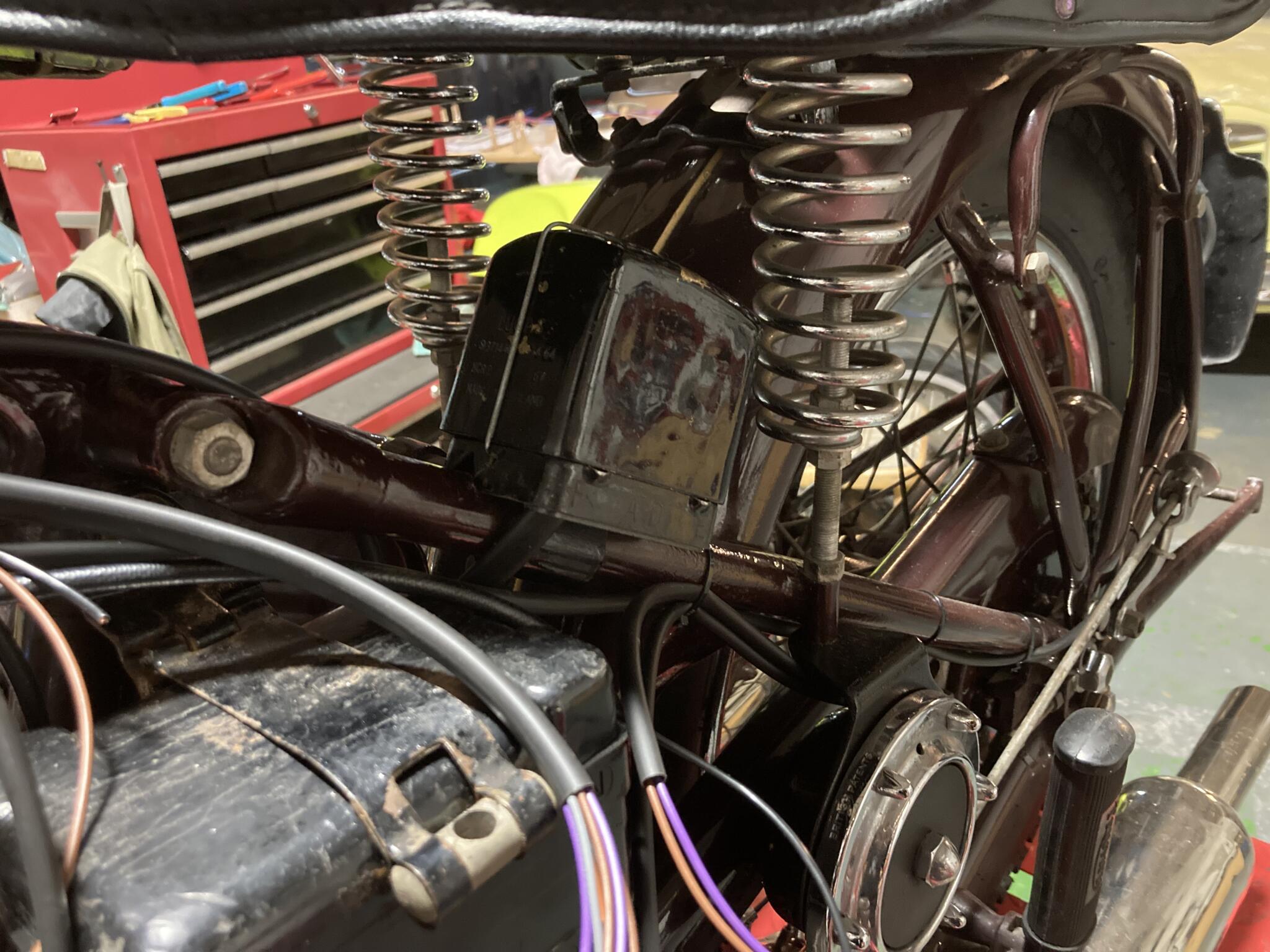

- Triumph made no effort when designing the bike to give the wires anywhere to go.

- The dash lives in the tank, and getting the tank on and off is a two-person job.

- The horn terminals almost touch the frame.

- The tail light wires run along a hinged rear mudguard, which if you unhinge it will wrench or snap the wires.

- The main light switch can’t separate pilot/tail on one position, and add headlight on the other one.

- Presumably to get round (3), the factory diagram shows two light bulbs in series, which is nuts.

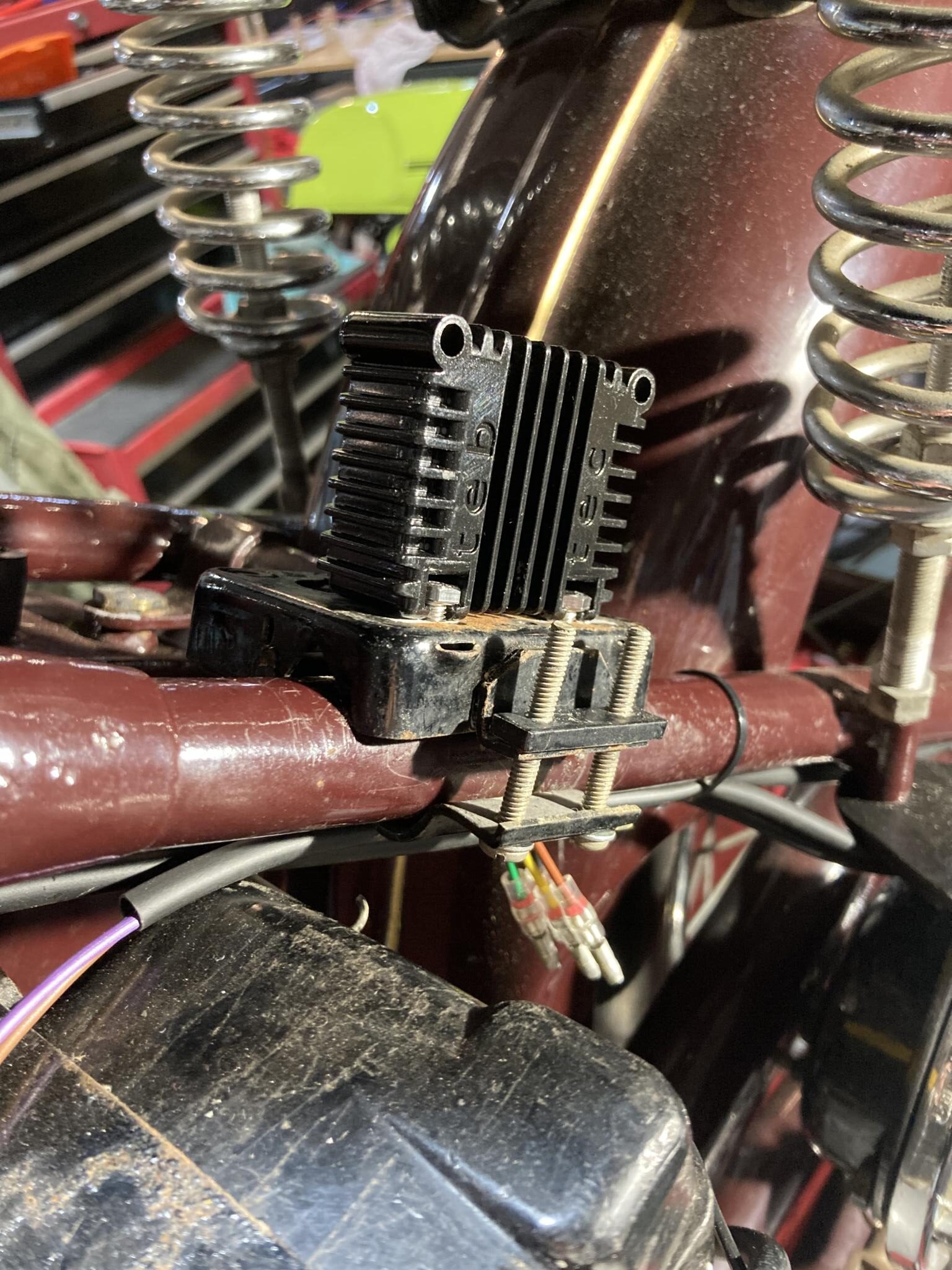

- The regulator (which obviously has to be replaced by a modern one) lives in a box. When you remove the original gubbins from said box, the lid doesn’t fit any more.

Paul warned me about most of these foibles when he brought the 500cc Triumph along. He’d found it in a collection which was being sold, and had recommissioned most of the bike in preparation for a summer’s riding. The wiring looked mostly original, which on a 1939 bike is quite something. The central dash featured a removable bulb on a long pair of wires. Paul explained the reason: “If you broke down at night you could lift the bulb out and look around the bike.” He knew this, because his Dad had a Speed Twin before him.

Paul was happy to forego the wandering light bulb and just leave it in place to illuminate the ammeter and oil pressure gauge. He also wanted a modern regulator. But the dynamo, 6V electrics and magneto ignition were all staying.

He’d found an old Triumph book with a Speed Twin wiring diagram, but once we’d looked closely it didn’t seem a good place to start. The speedo and tail light bulbs were in series, and the dash had multiple fiddly connections. We agreed to adopt the usual Brit arrangement where the horn and rear brake are permanently live, and you have two levels of lighting (pilot and full). The Triumph’s lighting switch turned out to be unable to provide this until I hit on using a diode to partly separate the pilot and main light circuits. I made it replaceable, even though diodes are tough as old boots.

We couldn’t fire the motor up after the loom build; the carb needed a little more work. But we were able to test Paul’s ignition timing settings. A squirt of Easy Start (or brake cleaner) in the carb is enough to make the engine run for a few revolutions. It sounded just fine.

It’s an honour to work on something this historic. Once the bike is finished it will be a delight on lazy sunny days.