Anthony’s R80 special

Anthony had bought the bike in bits and engaged various people to build it for him. The engine, wheels and paint looked really good. The forks were noisy, and the wiring loom was a rat’s nest using very cheap and fragile switchgear. Worse still the battery – a tiny lithium jobbie hidden inside the engine casing – was touching both its terminals on the said casing.

Anthony was after an everyday ride rather than a pub bike, so after a discussion he settled for an external gel battery, new switchgear, and a rewire using the lights it already had. This meant ordering a few bits, and making up a new battery box. Rather annoyingly, someone had chopped off the brackets for the old one. I wired up the peripheral bits and handed the bike over to my old mucker Rupe Farnsworth, who now trades as La Contenta Motorcycles.

Anthony asked if Rupe F could look at the forks, even though they had just been rebuilt. Rupe pressed and tigged up a very neat battery box, and fitted it using P-clips and existing seat brackets. When he removed the front wheel to look at the forks, a front wheel bearing fell out. There was no oil in the forks and the stanchions and sliders were so damaged they were both scrap. This from a so-called professional motorcycle shop who had charged proper money for the job.

Rupe found good new sliders and new stanchions at the excellent Motor Works. When the bike came back to me it had a plush front end and a properly-mounted gel battery.

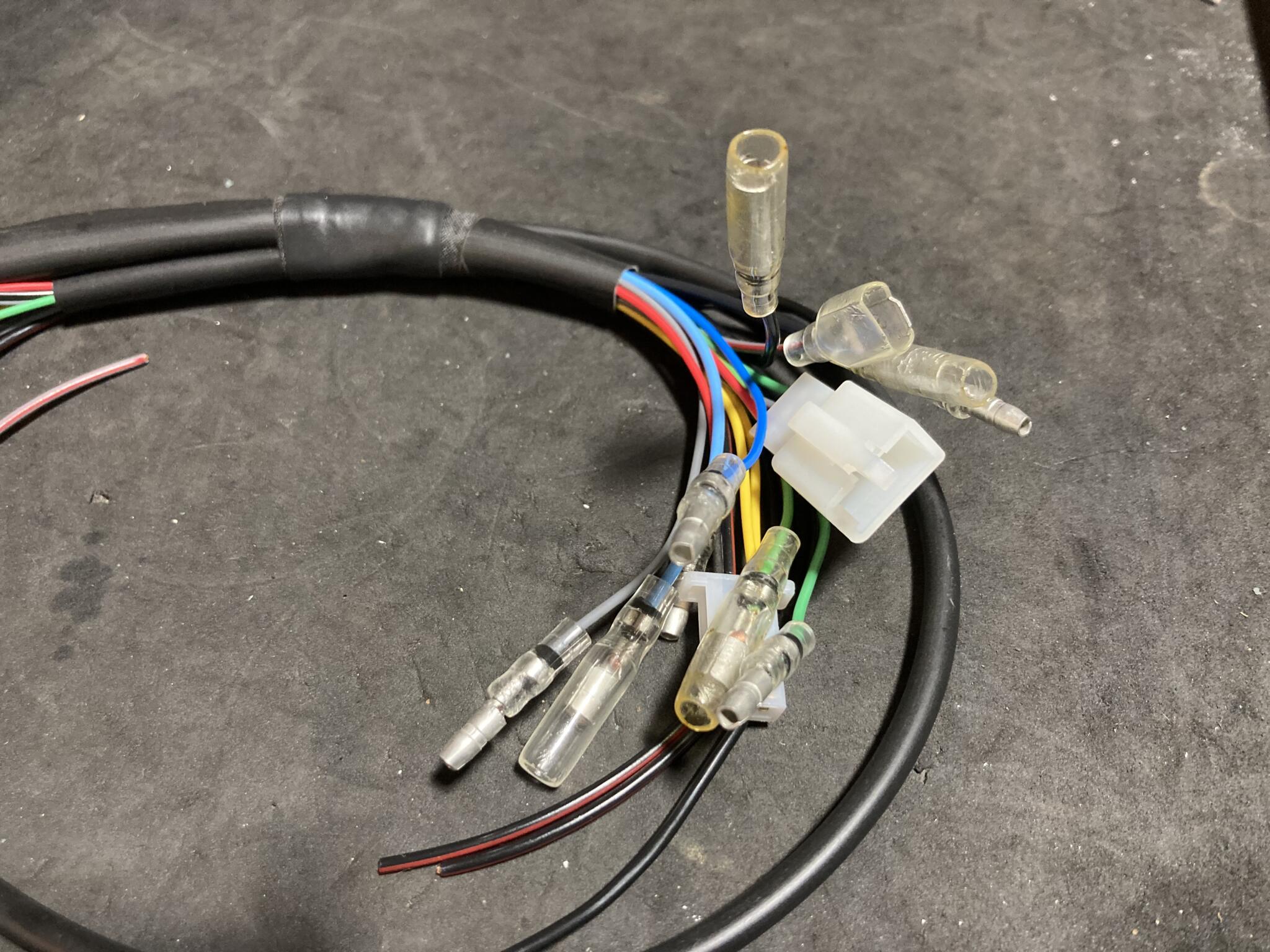

Making up the loom was pretty tricky because everything has to happen in an area under the tank about 12 inches long. It’s hard to make a job like that look elegant, but it can be robust and reliable. We’d sourced a new coil and HT lead kit from Motor Works too.

After almost three months of waiting and fiddling, it was a thrill to fire the bike up. It ran really nicely. Whoever built the engine and set up the carbs had done a fine job. All it needs now is the dash setting up, and a few hundred miles before the first service.

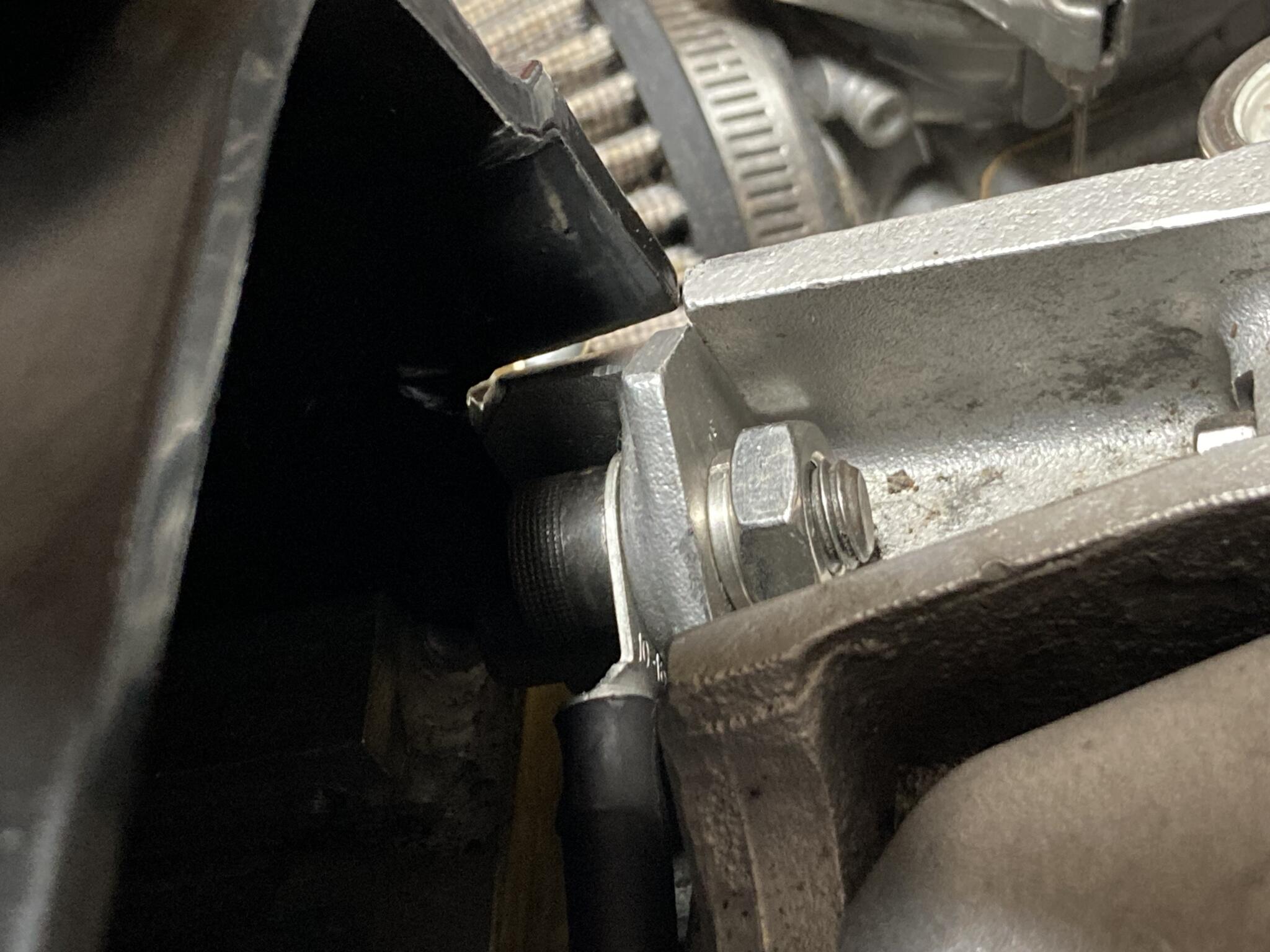

Boxer motors hide most of their charging and starting caboodle in the engine casing. Brass spacer keeps things tidy and unstressed

A boring picture of a nut under the engine case. Except it’s the best place on the bike to put a main battery earth

The final thing. With so little space I used tape as well as cable ties to make the wires clear the close-fitting fuel tank